The evolution of metal cutting technologies has positioned laser cutting as a superior alternative to traditional plasma cutting methods. Modern manufacturing demands increasingly precise tolerances, cleaner edges, and more efficient material utilization. While plasma cutting remains viable for specific applications, laser cutting systems demonstrate notable advantages in precision, versatility, and operational efficiency. These differences manifest across multiple performance metrics, fundamentally changing how industries approach metal fabrication.

Klíčové poznatky

Laser cutting achieves tighter tolerances (±0.1mm) and smoother edges than plasma cutting, reducing the need for post-processing operations.

While plasma cutting only works with conductive metals, laser cutting efficiently processes various materials including plastics, wood, and ceramics.

Laser cutting produces minimal heat-affected zones, resulting in less thermal distortion and higher quality cuts compared to plasma’s larger affected areas.

Advanced laser systems operate at speeds up to 20 meters per minute with optimized nesting patterns, maximizing material usage and production throughput.

Laser cutting requires less operator intervention and setup changes, reducing labor costs and improving workplace safety and efficiency.

Understanding the Core Differences Between Laser and Plasma Cutting

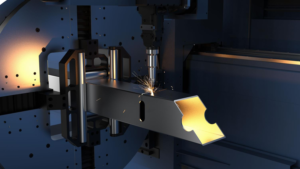

When comparing industrial cutting technologies, laser and plasma cutting systems operate on fundamentally different principles. Laser technology utilizes a focused beam of amplified light to create precise incisions through materials, while plasma cutting employs ionized gas to generate an electrical arc that melts through conductive metals.

The key distinction lies in their operational mechanisms. Laser systems concentrate photon energy into a narrow beam, achieving extremely precise cuts with minimal heat-affected zones. These systems can maintain consistent beam characteristics throughout the cutting process, resulting in superior edge quality. In contrast, plasma characteristics include a wider kerf width and larger heat-affected zones due to the nature of the ionized gas stream. The plasma process requires electrical conductivity in the workpiece, limiting its application primarily to metals, whereas laser cutting can process both conductive and non-conductive materials, including plastics, wood, and ceramics.

Superior Precision and Edge Quality in Laser Cutting

Laser cutting technology stands at the forefront of precision manufacturing due to its exceptional ability to produce clean, accurate cuts with minimal material deformation. The focused beam of coherent light delivers cutting accuracy within tolerances as tight as ±0.1mm, markedly outperforming plasma cutting methods.

The superior edge quality achieved through laser cutting is attributed to the concentrated heat zone and rapid vaporization process. This results in consistently smooth edges that typically require minimal post-processing. The high-energy density of the laser beam creates a precise kerf width, reducing material waste and preventing thermal distortion in surrounding areas.

Modern laser cutting systems utilize advanced beam control mechanisms to maintain edge smoothness across varying material thicknesses. The process eliminates common issues found in plasma cutting, such as bevel angles and dross formation, resulting in parts that meet strict quality control standards for industrial applications.

Material Waste Reduction and Cost Efficiency

Through optimized nesting algorithms and minimal kerf width requirements, modern laser cutting systems markedly reduce material waste compared to traditional cutting methods. The sophisticated software calculates the most efficient arrangement of parts on raw material sheets, maximizing yield and minimizing scrap generation. This material optimization directly translates to significant cost savings in production processes.

The economic impact of laser cutting extends beyond material conservation. The precise beam control allows for narrower cutting paths, enabling more parts to be cut from a single sheet. Additionally, the reduced need for secondary finishing operations and lower maintenance requirements contribute to overall operational efficiency. The technology’s ability to process multiple part variations within the same setup further enhances cost-effectiveness by eliminating tool changes and reducing setup times. These combined advantages result in lower per-part costs, improved material utilization rates, and enhanced production throughput compared to conventional cutting methods.

Speed and Production Throughput Comparison

Modern manufacturing facilities consistently demonstrate that laser cutting systems outperform traditional cutting methods in terms of production speed and throughput capacity. These systems achieve higher cutting speeds while maintaining superior precision, particularly when processing thin to medium-thickness materials.

The speed advantages of laser cutting become evident in high-volume production environments, where the technology can process multiple parts simultaneously through optimized nesting patterns. Advanced laser systems operate at speeds up to 20 meters per minute on thin materials, substantially surpassing plasma cutting rates. The automated nature of laser cutting systems also reduces setup time between different production runs.

Production capacity increases further through reduced maintenance requirements and minimal tool changes. While plasma cutting may offer faster speeds on very thick materials, laser cutting maintains consistent throughput across varied production schedules, enabling manufacturers to meet demanding delivery timelines with greater reliability and operational efficiency.

Versatility Across Different Materials and Thicknesses

The adaptability of laser cutting technology extends beyond speed advantages to encompass a wide range of materials and thicknesses. The system demonstrates superior material adaptability, efficiently processing metals, plastics, wood, ceramics, and composites with minimal setup changes. This versatility eliminates the need for multiple specialized cutting systems in manufacturing facilities.

Laser cutting’s thickness versatility allows precise operations across varying material dimensions, from thin foils measuring fractions of a millimeter to structural plates several centimeters thick. The technology maintains consistent cut quality throughout different thickness ranges by automatically adjusting beam focus, power settings, and cutting parameters. This automated optimization guarantees clean edges and minimal heat-affected zones regardless of material composition or thickness.

The system’s ability to shift seamlessly between materials and thicknesses reduces production bottlenecks and tooling requirements, making it particularly valuable in mixed-material manufacturing environments where operational flexibility is vital.

Advanced Control Systems and Automation Benefits

Modern laser cutting systems incorporate advanced motion control systems that synchronize multiple axes with microsecond precision. Integrated software platforms enable seamless coordination between CNC parameters, laser power modulation, and material handling automation. These sophisticated control systems optimize cutting paths, reduce setup times, and maintain consistent quality across production runs through automated parameter adjustments.

Precision Motion Control Systems

Advanced precision motion control systems revolutionize laser cutting operations by integrating sophisticated servo motors, linear encoders, and real-time feedback mechanisms. These systems enable accurate motion tracking along multiple axes while maintaining consistent cutting speeds and positioning accuracy within microns.

The integration of closed feedback loops continuously monitors and adjusts the cutting head’s position, ensuring ideal beam focus and cut quality throughout the process. Modern motion control systems compensate for mechanical variables such as acceleration, deceleration, and vibration in real-time, minimizing deviation from programmed cutting paths. This level of precision control allows manufacturers to achieve complex geometries and maintain tight tolerances across diverse material types and thicknesses, resulting in superior edge quality and dimensional accuracy compared to conventional cutting methods.

Software Integration Benefits

Integrated software solutions enhance precision motion control systems by streamlining workflow automation and improving cutting parameters in real-time. Modern CAD/CAM software compatibility guarantees seamless design integration from concept to production, minimizing setup time and material waste.

| Software Feature | Automation Benefit |

|---|---|

| Nesting Algorithm | Material Improvement |

| Path Planning | Reduced Cycle Time |

| Quality Control | Real-time Monitoring |

Advanced control systems automatically adjust cutting parameters based on material thickness, composition, and surface conditions. These intelligent systems continuously monitor process variables, maintaining peak cutting performance while reducing operator intervention. The integration of production planning software with machine controls enables efficient scheduling, real-time tracking, and thorough quality reporting, resulting in enhanced productivity and consistent output quality.

Conclusion

Laser cutting’s superior efficiency over plasma cutting is evidenced through multiple technical advantages, particularly in precision and waste reduction. Studies indicate that laser cutting can achieve tolerances as precise as ±0.1mm, compared to plasma’s ±0.5mm, representing an 80% improvement in accuracy. This precision, combined with automated control systems and minimal heat-affected zones, establishes laser cutting as the best choice for modern manufacturing operations requiring high accuracy and material optimization.