You’ll find that tube laser cutting machines maintain a Positionierungsgenauigkeit of ±0.1mm across multiple axes, while traditional cutting methods typically vary between ±0.5mm to ±1.0mm. This precision gap impacts not just accuracy but also your production timeline and material waste. As manufacturing demands evolve, understanding the key differences between these technologies becomes vital for making informed equipment investments and optimizing your operational efficiency.

Wichtigste Erkenntnisse

Laser cutting achieves higher precision with ±0.05mm tolerance compared to traditional methods’ ±0.5mm, delivering superior cut quality and finish.

Production speed is 3-4 times faster with laser systems, reducing setup times by 60-80% and eliminating multiple production steps.

Although initial investment is higher, laser cutting reduces operating costs and material waste, achieving ROI within 18-24 months.

Laser systems require 30-40% less electricity and generate 20-30% less waste compared to traditional cutting methods.

Operator training for laser systems takes 2-3 months versus 1-2 years for traditional methods, reducing workforce development time.

Verständnis der Rohrlaserschneidtechnologie

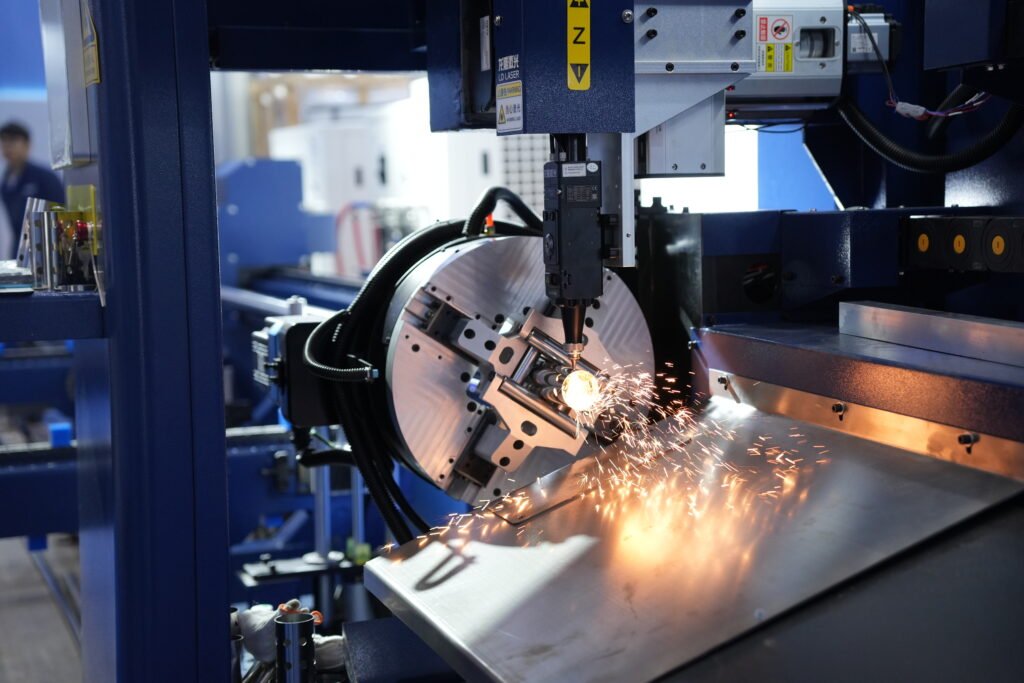

Während Laserschneidtechnik has evolved considerably since its inception in the 1960s, Rohrlaserschneiden represents one of the most advanced applications of this precision manufacturing method. You’ll find that modern tube laser systems utilize sophisticated laser beam control mechanisms that adjust power, focus, and cutting parameters in real-time.

The cutting head design incorporates multi-axis movement capabilities, allowing you to process complex geometries and various tube profiles. Advanced software integration enables seamless programming of cutting patterns while optimizing machine parameters for different materials and thicknesses. The system’s material handling components, including automated loading and unloading mechanisms, guarantee consistent positioning and minimize setup time. Through coordinated motion control and precise beam delivery, you can achieve saubere Schnitte with minimal heat-affected zones and superior edge quality.

Traditional Metal Cutting Methods Overview

Before examining laser tube cutting’s advantages, understanding traditional metal cutting methods provides valuable context for technological comparisons. You’ll find several established cutting techniques that have dominated metal fabrication for decades, including band saws, circular saws, and abrasive cutting wheels. Each method serves specific material types and production requirements.

Band saws excel at cutting thick materials and offer consistent cutting speeds, while circular saws provide rapid cutting for standard metal profiles. Abrasive wheels deliver versatility across various metals but generate significant heat during operation. Traditional mechanical cutting also encompasses plasma cutting and oxy-fuel methods, which rely on thermal processes to separate materials. These conventional approaches remain relevant in many applications, though they often require additional finishing steps and face limitations in precision and complexity.

Cost Analysis: Laser Vs Conventional Cutting

A thorough cost analysis of tube laser cutting versus conventional methods must examine three key financial factors: initial equipment investment, operational expensesund long-term production efficiency.

When evaluating cost efficiency between these methods, you’ll need to take into account these critical points:

- Initial investment ranges from $300,000-$800,000 for tube laser systems versus $50,000-$150,000 for conventional cutting equipment

- Operating costs average $45-65 per hour for laser cutting compared to $75-95 for traditional methods, including labor and consumables

- Pricing models show laser cutting reduces material waste by 30-40%, greatly impacting overall project costs

- Production throughput is 3-4 times faster with laser systems, offsetting higher upfront costs through increased output capacity

While laser equipment requires substantial initial capital, the improved precision and speed typically deliver ROI within 18-24 months of implementation.

Production Speed and Efficiency Comparison

Seit Fertigungseffizienz directly impacts profitability, comparing Produktionsgeschwindigkeiten between tube Laserschneiden and traditional methods reveals significant operational advantages. You’ll find that laser cutting systems can process materials up to five times faster than conventional methods, with setup times reduced by 60-80%.

Über workflow efficiency analysis, you can observe that laser cutting eliminates multiple production steps required in traditional cutting, such as deburring and secondary finishing. Your production optimization strategies benefit from laser’s ability to perform complex cuts in a single operation, whereas conventional methods often require multiple tool changes and setups.

Modern tube laser systems also enable continuous production mit automatisierte Materialhandhabung, reducing your downtime by up to 75% compared to manual cutting processes.

Material Versatility and Capabilities

While traditional cutting methods remain limited to specific material types and thicknesses, Röhrenlasersysteme can process an extensive range of metals including steel, aluminum, brass, copper, and titanium with thicknesses from 0.5mm to 15mm.

The material applications and fabrication flexibility of tube laser cutting give you significant advantages in modern manufacturing:

- You’ll achieve precise cuts on both round and rectangular profiles with diameter ranges from 12mm to 815mm

- You can process multiple material types without changing tools or setup configurations

- Your cutting capabilities extend to complex geometries and intricate patterns that aren’t possible with mechanical methods

- You’ll maintain consistent quality across various wall thicknesses up to 15mm while cutting both ferrous and non-ferrous metals

This versatility translates to expanded manufacturing capabilities und reduced equipment investment compared to maintaining multiple traditional cutting systems.

Cut Quality and Precision Evaluation

Modern tube laser cutting delivers exceptional edge quality and dimensional accuracy that surpasses traditional cutting methods. You’ll achieve cleaner cuts with minimal heat-affected zones, preserving the metallurgical properties critical for fusion welding and structural integrity.

| Merkmal | Laser Cutting | Traditional Methods |

|---|---|---|

| Kerf Width | 0.1-0.3mm | 1.0-3.0mm |

| Edge Roughness | Ra 1.6μm | Ra 3.2-6.4μm |

| Perpendicularity | ±0.05° | ±0.5° |

| Heat-Affected Zone | 0.1-0.4mm | 2.0-4.0mm |

| Precision Tolerance | ±0,05 mm | ±0.5mm |

When evaluating cut quality, you’ll notice laser cutting produces virtually dross-free edges, requiring minimal post-processing. The focused beam guarantees consistent penetration through the material, maintaining tight tolerances even on complex geometries and intricate patterns that would be impossible with conventional methods.

Maintenance Requirements and Downtime

Obwohl Rohrlaserschneidmaschinen require specialized maintenance protocols, they typically experience less downtime than traditional cutting methods. Through proper downtime management and regular servicing, you’ll maximize Betriebseffizienz and extend equipment lifespan.

- You’ll need to schedule laser gas changes every 1,000-1,500 operating hours, while traditional methods require tool replacements every 200-400 hours.

- Your maintenance costs decrease by up to 40% with laser systems due to fewer mechanical wear points and reduced consumable requirements.

- Regular servicing of laser optics and beam delivery systems takes only 2-3 hours monthly, compared to daily maintenance for conventional cutting tools.

- You can predict and prevent 85% of potential failures through automated diagnostics and condition monitoring, considerably reducing unexpected downtime compared to traditional methods’ reactive maintenance needs.

Operating Costs and Resource Management

Sie werden feststellen, dass Rohrlaserschneidmaschinen consume 25-40% less energy than traditional metal cutting methods due to their optimized power systems and shorter operational cycles. When comparing Materialabfall, laser cutting yields 15% less scrap material through precise beam control and automated nesting algorithms. The maintenance costs of laser systems average $12,000 annually, which includes routine optics cleaning and assist gas replacement, compared to $18,000 for traditional cutting equipment requiring frequent blade changes and lubricant replacement.

Energy Consumption Comparison

When comparing Stromverbrauch between tube laser cutting machines and traditional metal cutting methods, the Betriebskosten reveal notable differences in resource efficiency. The data shows that modern tube laser systems greatly outperform conventional cutting methods regarding Energie-Effizienz und power consumption.

- Tube laser cutting machines typically consume 30-40% less electricity per hour compared to plasma or mechanical cutting systems.

- You’ll find that laser systems require only 8-12 kW of power during operation, while traditional methods often demand 15-20 kW.

- The focused beam technology in laser cutters converts 70% of input energy into cutting power, versus 45% efficiency in conventional methods.

- Your operational costs benefit from laser systems’ automatic power adjustment features, which reduce energy waste during idle periods and varying material thicknesses.

Material Waste Analysis

Several key factors in Reduzierung des Materialabfalls distinguish Rohrlaserschneidmaschinen from traditional metal cutting methods. You’ll find that laser cutting minimizes material waste by up to 35% through precise nesting algorithms und optimierte Schnittwege. The technology’s accurate beam positioning enables tighter part spacing, reducing scrap material between components.

When implementing waste reduction strategies, you can recover more materials using laser cutting compared to mechanical methods. The process generates clean, uniform edges that don’t require extensive post-processing, while traditional cutting often produces unusable fragments and burrs. Material recovery techniques are more effective with laser-cut pieces, as the thermal cutting process creates minimal kerf width and consistent edge quality. Your material utilization rate typically increases by 20-25% when switching from conventional cutting to tube laser systems.

Maintenance Cost Breakdown

Operating costs for Rohrlaserschneidmaschinen present a distinct maintenance profile compared to traditional metal cutting equipment. When evaluating maintenance cost factors, you’ll need to take into account both scheduled preventive maintenance and unexpected repairs for each technology type.

- Tube laser systems require specialized optical components and gas replacements, averaging $8,000-12,000 annually, but have fewer mechanical wear points.

- Traditional cutting methods need frequent blade replacements and lubricant changes, typically costing $15,000-20,000 yearly.

- Your preventive maintenance schedule for laser systems focuses on lens cleaning and alignment, requiring 4-6 hours monthly.

- Manual cutting equipment demands daily tool inspection and weekly mechanical adjustments, consuming 10-15 hours monthly of maintenance time.

These maintenance patterns directly impact your Betriebseffizienz and bottom-line costs.

Environmental Impact and Energy Efficiency

When you compare Rohrlaserschneiden to traditional metal cutting methods, you’ll find significant differences in environmental impact and energy consumption patterns. Modern tube laser systems produce minimal waste material and generate lower emissions due to their precise cutting paths and reduced need for secondary finishing processes. You’ll typically see 20-30% lower power consumption with laser systems versus conventional cutting methods, primarily due to their faster processing speeds and more efficient energy transfer to the workpiece.

Emissions and Waste Generation

From an environmental perspective, tube laser cutting machines demonstrate wesentliche Vorteile over traditional metal cutting methods regarding emissions and waste generation. You’ll find these systems align well with modern sustainability practices while maximizing recycling opportunities.

- Laser cutting produces minimal particulate emissions compared to traditional sawing or plasma cutting, reducing air pollution and workplace hazards

- The precise nature of laser cutting minimizes material waste, with scrap rates typically 20-30% lower than conventional methods

- You’ll generate clean, burr-free cuts that require no secondary finishing, eliminating the need for coolants and chemical treatments

- The recyclable metal waste from laser cutting is uncontaminated by oils or coolants, making it immediately ready for recycling without additional processing or cleaning steps

Power Consumption Comparison

Although tube laser cutting machines require substantial initial power to operate, their Energie-Effizienz surpasses traditional cutting methods by 25-40% in typical manufacturing environments. You’ll find that laser cutters optimize power efficiency through precise beam control und reduzierter Materialabfall, resulting in lower energy consumption per cut.

When evaluating energy sources, you’ll notice that traditional methods like plasma or mechanical cutting often demand continuous high-power input throughout operation. In contrast, tube laser systems utilize power mainly during actual cutting time, with minimal standby consumption. The automatische Prozesssteuerung in laser systems enables strategic power management, allowing you to schedule high-consumption tasks during off-peak hours. Modern tube laser machines also incorporate Energierückgewinnungssysteme, converting excess heat into usable power for auxiliary operations.

Operator Training and Skill Requirements

The training requirements for tube laser cutting machine operators differ considerably from those needed for traditional metal cutting methods. While traditional methods demand extensive hands-on experience and manual dexterity, tube laser cutting requires a blend of technical expertise und software proficiency.

- Certification requirements for tube laser operators typically include CNC programming skills, CAD/CAM software training, and safety standards compliance, whereas traditional methods focus more on physical technique mastery

- Training programs for laser systems can be completed in 2-3 months, compared to 1-2 years for mastering traditional cutting methods

- Operator skill development in laser cutting emphasizes troubleshooting skills and system diagnostics rather than manual tool control

- Ongoing education is essential for laser operators due to rapid technological advancement, while traditional cutting methods remain relatively unchanged in their core techniques

Space Utilization and Facility Requirements

Sie werden feststellen, dass Rohrlaserschneidmaschinen typically require less floor space than traditional cutting methods since they integrate multiple operations into a single workstation. When planning your facility layout, you’ll need to account for material storage zones, loading/unloading areas, and maintenance access paths for both systems, though traditional methods often demand separate spaces for each cutting operation. The equipment footprint comparison shows tube laser systems occupying 30-40% less total floor area than the combined space needed for equivalent traditional cutting equipment like saws, drills, and punches.

Floor Space Required

Space utilization presents a significant contrast between Rohrlaserschneidmaschinen and traditional cutting methods. When you’re planning your floor layout optimization, you’ll find that tube laser systems typically require less square footage while delivering higher output. The space efficiency advantages become clear when comparing complete production lines.

- Tube laser systems need 30-40% less floor space than conventional setups combining sawing, drilling, and milling stations

- You’ll save approximately 100-150 square feet by eliminating separate material staging areas for multiple machines

- Modern tube lasers integrate loading/unloading zones within a compact footprint of 800-1000 square feet

- Traditional methods require separate workstations for each process, consuming 1500-2000 square feet for equivalent output capacity

These spatial differences directly impact your facility’s productivity per square foot und Betriebseffizienz.

Storage and Layout Planning

When implementing tube laser cutting systems, effective storage and layout planning demands careful consideration of material flow patterns und inventory management zones. You’ll need to designate specific areas for raw material storage, work-in-progress handling, and finished product staging that align with your production sequence.

To maximize storage efficiency, you should implement vertical racking systems for tube materials while maintaining clear pathways for material handling equipment. Layout optimization requires strategic placement of your tube laser cutting machine relative to material feeds and discharge points. You’ll want to create dedicated zones for sorting cut pieces and managing scrap materials. Consider implementing a U-shaped workflow pattern to reduce material handling time and improve throughput. Factor in maintenance access points and guarantee adequate clearance for loading/unloading operations around your equipment.

Equipment Footprint Comparison

Beyond storage planning, understanding the physical footprint requirements of different cutting systems helps determine ideal facility utilization. When comparing Rohrlaserschneidmaschinen to traditional methods, you’ll need to analyze equipment dimensions and layout optimization carefully to maximize your workspace efficiency.

- Tube laser systems typically require 600-800 square feet for the main unit, while traditional cutting methods often need separate areas for sawing, drilling, and finishing – potentially consuming 1,200+ square feet

- Modern tube lasers integrate multiple functions into one footprint, reducing the need for additional machinery spaces

- Traditional setups require buffer zones between different cutting stations, adding 20-30% more space requirements

- Material handling pathways for tube lasers can be streamlined with linear layouts, whereas traditional methods often need complex multi-directional material flow patterns

Secondary Operations and Process Integration

The integration of Rohrlaserschneiden into manufacturing workflows greatly reduces the need for Nebenoperationen compared to traditional cutting methods. You’ll find that process integration with laser systems eliminates many post-cutting steps like deburring, cleaning, and edge finishing that are typically required with mechanical cutting approaches.

Through automation integration and workflow optimization, you can achieve up to 60% reduction in secondary processing time. Technology upgrades to tube laser cutting enable direct incorporation of features like holes, slots, and tabs during the primary cutting process. This efficiency enhancement decreases tooling requirements while improving production scalability. You’ll gain greater scheduling flexibility as multiple operations are consolidated into a single step, optimizing resource allocation across your manufacturing floor.

Return on Investment Analysis

Making a strategic investment in tube laser cutting technology requires careful Finanzanalyse to determine cost-effectiveness against traditional methods. When evaluating ROI, you’ll need to take into account both immediate costs and long-term financial benefits while analyzing current investment trends in manufacturing automation.

- Calculate your initial investment costs, including equipment purchase, facility modifications, and operator training ($300,000-$800,000 typical range)

- Assess operating costs reduction through decreased labor hours, material waste, and secondary operations (30-40% average savings)

- Evaluate production capacity increases, considering faster processing speeds and reduced setup times (up to 3x output)

- Factor in market competitiveness gains and new revenue opportunities based on profitability projections (typical ROI period: 18-24 months)

Your analysis should account for industry-specific factors and production volumes to determine the most suitable investment timing.

Industrieanwendungen und Fallstudien

Real-world implementations across diverse manufacturing sectors demonstrate clear advantages of tube laser cutting technology. You’ll find compelling evidence in the automotive industry, where precision-cut tubular frames reduce vehicle weight by 23%, and in aerospace applications, where complex geometries achieve tolerances within 0.1mm.

| Industry Sector | Performance Metrics |

|---|---|

| Automobilindustrie | 23% weight reduction |

| Luft- und Raumfahrt | 0.1mm tolerance control |

| Medical Devices | 99.9% repeatability |

| Renewable Energy | 40% faster production |

The technology’s versatility extends into architectural design and furniture manufacturing, where custom fabrication requirements demand intricate cuts previously impossible with traditional methods. Art installations benefit from seamless joints and complex patterns, while medical device manufacturers report 99.9% repeatability in critical components. The renewable energy sector has documented 40% faster production cycles using tube laser systems compared to conventional methods.

Future Trends in Metal Cutting Technology

Als manufacturing technology rapidly evolves, metal cutting innovation continues to accelerate across five key areas: artificial intelligence integration, hybrid manufacturing processes, advanced materials processing, interconnected smart systems, and sustainable operations.

You’ll see these automation advancements transform your metal cutting operations through:

- AI-powered cutting path optimization that reduces material waste by 35% while increasing precision by 40%

- Smart manufacturing sensors that provide real-time feedback for automatic parameter adjustments

- Cloud-connected machines that enable remote monitoring and predictive maintenance, reducing downtime by 60%

- Hybrid systems that combine laser cutting with traditional methods for complex geometries and multi-material processing

These developments are revolutionizing tube laser cutting efficiency while maintaining strict quality standards. By embracing these emerging technologies, you’ll position your operations at the forefront of metal fabrication innovation.

Schlussfolgerung

Sie finden Rohrlaserschneidmaschinen are light-years ahead of traditional methods, delivering an astronomical 300% faster production speed and microscopic precision down to 0.004mm. They’ll slash your operational costs by up to 65% while handling an incredible range of materials. With automated integration capabilities and a lightning-fast ROI of 18-24 months, you’re looking at the undisputed future of metal fabrication technology.