Like a precision surgeon’s scalpel, corte por láser de tubos has carved out a revolutionary niche in modern manufacturing. You’ll find this technology transforms how industries approach tubular material processing, offering unprecedented accuracy and design flexibility. Through advanced beam control and sophisticated programming, you can now achieve complex geometries that weren’t possible with traditional methods. Yet the true potential of tube laser cutting extends far beyond these initial capabilities.

Principales conclusiones

Tube laser cutting achieves complex geometries and intricate patterns with exceptional precision, maintaining tolerances as tight as ±0.1mm.

Automated processes reduce cycle times by 40% while enabling 24/7 operation for maximum production efficiency.

Advanced nesting software and AI-driven systems minimize material waste by up to 40%, significantly reducing production costs.

Integration of smart sensors and real-time monitoring ensures consistent quality control with deviation detection as small as 0.001 inches.

Multiple manufacturing steps are consolidated into a single process, streamlining production and eliminating separate operations.

Tecnología de corte por láser de tubos

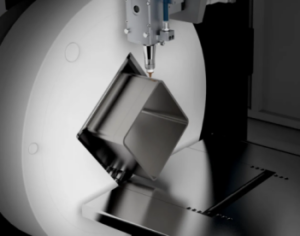

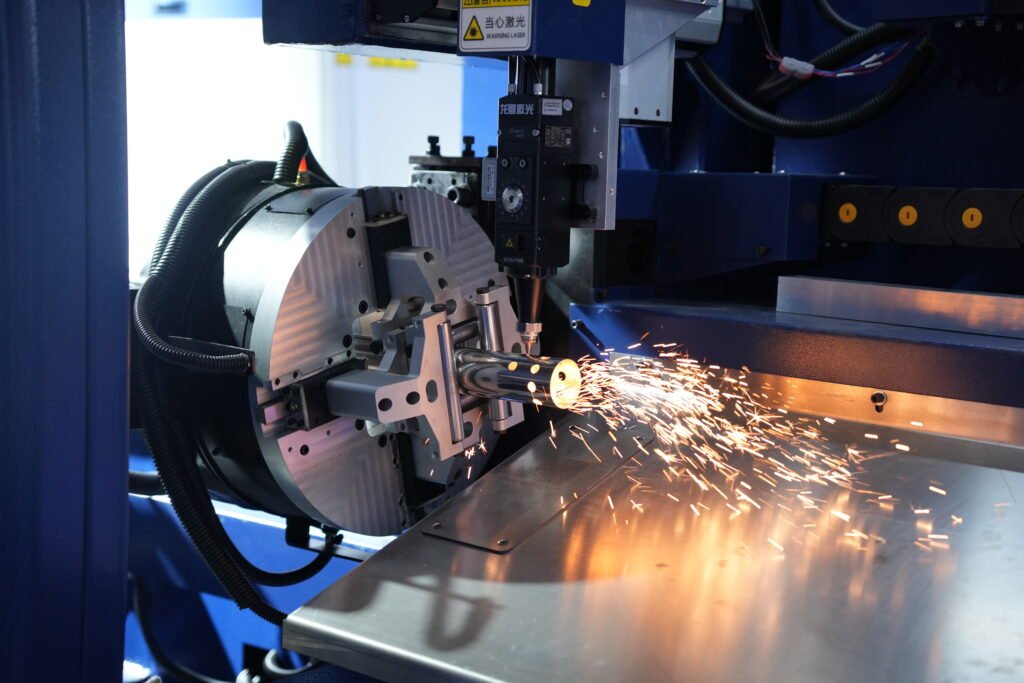

While traditional cutting methods have served manufacturing well for decades, corte por láser de tubos represents a significant technological advancement in precision fabrication. You’ll find this technology employs focused laser beams that precisely cut various tube types, including round, square, rectangular, and oval profiles.

The process relies on sophisticated beam dynamics, where a high-powered laser creates a concentrated point of energy that melts or vaporizes material along the cutting path. You’re able to achieve complex geometries and intricate patterns that would be difficult or impossible with conventional methods. The laser’s beam characteristics, including focal length, power density, and pulse frequency, directly influence the cut quality. By controlling these parameters, you can optimize the cutting process for different material thicknesses and compositions while maintaining precisión excepcional and edge finish.

Key Benefits and Industry Applications

Verá que tube laser cutting technology delivers precisión excepcional at high speeds, allowing for intricate cuts and complex geometries without compromising production rates. The process reduces material waste and labor costs while minimizing secondary operations, making it a cost-effective solution for manufacturers across industries. From automotive exhaust systems to architectural frameworks, tube laser cutting enables advanced manufacturing capabilities that surpass traditional methods in both quality and versatility.

Unmatched Precision and Speed

Laser-powered tube cutting delivers unmatched precision y remarkable speed compared to traditional cutting methods. When you’re working with precision engineering projects, you’ll achieve tolerances as tight as ±0.1mm while maintaining exceptional surface finish quality. The system’s rapid prototyping capabilities let you move from design to finished parts in a fraction of the time required by conventional methods.

- You’ll cut complex geometries with zero tool changes, reducing production time by up to 75%

- Your parts will maintain consistent quality through automated process monitoring

- You’ll eliminate secondary operations with clean, burr-free edges straight from the machine

- Your material waste will decrease by up to 30% through optimized nesting algorithms

The combination of speed and accuracy transforms your manufacturing workflow, making tube laser cutting essential for modern production environments.

Cost-Efficient Production Solutions

Beyond speed and precision advantages, corte por láser de tubos transforms your production economics through multiple cost-saving mechanisms. You’ll reduce residuos materiales by up to 30% through optimized nesting and cutting patterns, while minimizing post-processing requirements and secondary operations.

The technology delivers significant cost savings by consolidating multiple manufacturing steps into a single process. You’ll eliminate the need for separate drilling, sawing, and notching operations, reducing both labor costs and equipment investments. Production efficiency increases as you shift from manual to automated processes, enabling 24/7 operation with minimal operator intervention. Additionally, your quality control costs decrease due to the consistent accuracy of laser-cut components, resulting in fewer rejections and reduced material scrap. These efficiencies translate directly to improved profit margins and competitive market pricing.

Advanced Manufacturing Capabilities

While traditional tube fabrication methods face limitations, tube laser cutting technology opens up unprecedented manufacturing capabilities across diverse industries. The integration of smart manufacturing principles enables you to achieve superior precision and production scalability while maintaining consistent quality across complex geometries.

- You’ll gain micron-level cutting accuracy (±0.1mm) across various materials including stainless steel, aluminum, and carbon steel tubes up to 8 inches in diameter

- Your production line can handle dynamic contour cutting with 5-axis manipulation for intricate joint designs and complex bevels

- You’re able to achieve automated material handling with real-time process monitoring for continuous operation

- Your manufacturing capabilities extend to include both small prototype runs and high-volume production without compromising on edge quality or dimensional accuracy

Advanced Features of Modern Tube Cutting Systems

Modern tube cutting systems incorporate sophisticated features that extend far beyond basic cutting operations. You’ll find advanced software platforms that enable precise control over cutting parameters, plus customizable settings for different materials and geometries. These systems optimize your workflow through intelligent automation.

| Característica | Capability | Benefit |

|---|---|---|

| Auto-Focus | Dynamic beam adjustment | Consistent cut quality |

| Smart Sensing | Material detection | Reduced setup time |

| 3D Mapping | Spatial awareness | Complex geometry handling |

| Process Monitor | Real-time feedback | Quality assurance |

Today’s cutting systems integrate seamlessly with CAD/CAM environments, allowing you to shift from design to production efficiently. The machines automatically compensate for material variations and thermal effects, ensuring your cuts maintain tight tolerances throughout extended production runs.

Design Possibilities and Engineering Innovation

The engineering capabilities of tube laser cutting systems open up unprecedented design possibilities across multiple industries. With advanced software integration and precise control systems, you’ll access new potential for design innovation that wasn’t possible with traditional manufacturing methods.

- Your design innovation can now include complex geometric patterns and intricate cutouts that transform simple tubes into functional art pieces.

- You’re able to create precise interlocking joints and custom fitting components that revolutionize assembly processes.

- Through engineering creativity, you can develop lightweight yet strong structural elements by strategically placing cuts and reliefs.

- You’ll achieve seamless integration of multiple components by designing complementary features directly into the tubular structure.

These capabilities extend beyond mere aesthetics, enabling you to optimize material usage, reduce assembly time, and enhance integridad estructural simultaneously.

Cost-Efficiency and Material Optimization

Smart implementation of corte por láser de tubos delivers substantial cost advantages through precise material utilization and reduced waste. You’ll achieve significant cost savings by optimizing material usage through advanced nesting software that maximizes the number of parts per tube length. The technology’s precision cutting capabilities minimize material waste to less than 1% in many applications.

You can further reduce costs by eliminating operaciones secundarias like deburring and cleaning, as laser cuts produce clean edges that often require no additional finishing. The process’s speed and automation decrease labor costs while increasing throughput. When you integrate design optimization with material selection, you’ll find opportunities to reduce material thickness or choose alternative alloys without compromising structural integrity, leading to additional cost reductions in raw materials and processing time.

Precision and Quality Control Standards

Encontrará automated measurement systems integrated throughout modern tube laser cutting operations, ensuring consistent precisión dimensional and surface finish quality. These systems employ advanced sensors and real-time monitoring technology to detect deviations as small as 0.001 inches while maintaining ISO 9001 certification standards. To meet industry requirements, your quality control process must incorporate regular calibration checks, documented inspection procedures, and compliance with specific tolerances defined by ASTM International and AWS D1.1 specifications.

Automated Measurement Systems

Maintaining precise dimensional accuracy in tube laser cutting requires sophisticated automated measurement systems that integrate directly with quality control protocols. You’ll find that modern measurement integration enables real-time monitoring y instant adjustments during the cutting process, ensuring consistent quality across production runs.

- Your automated calibration systems continuously verify dimensional accuracy to within ±0.001 inches, preventing costly material waste

- You’re able to track and analyze measurement data across multiple production shifts, identifying potential drift patterns before they impact quality

- Your integrated measurement systems provide instant feedback loops that automatically adjust cutting parameters

- You’ll achieve superior repeatability through synchronized measurement protocols that simultaneously monitor multiple geometric features

These systems interface seamlessly with your quality management software, creating an extensive dataset that supports both production efficiency and regulatory compliance.

Industry Certification Requirements

The tube laser cutting industry adheres to strict certification requirements governed by international standards organizations like ISO, AWS, and ASME. You’ll need to maintain compliance guidelines and obtain relevant certifications from accredited certification bodies to operate professionally in this field.

| Standard | Requirement | Renewal Period |

|---|---|---|

| ISO 9001 | Quality Management | 3 years |

| AWS D17.1 | Fusion Welding | 2 years |

| ASME B31.3 | Process Piping | 5 years |

Your facility must implement rigorous quality control procedures, maintain detailed documentation of all processes, and regularly calibrate equipment to meet these standards. You’re required to undergo periodic audits and inspections to verify compliance with industry regulations. Training and certification of operators must be current, with regular assessments to guarantee continued competency in tube laser cutting operations.

Manufacturing Process Improvements

Implementing strategic improvements in tube laser cutting processes can greatly enhance eficacia de fabricación and product quality. You’ll find that adopting efficiency strategies and process optimization techniques transforms your production workflow. By analyzing your current operations and implementing data-driven solutions, you can achieve measurable improvements in throughput and precision.

- Streamline your material handling systems by integrating automated loading/unloading mechanisms, reducing cycle times by up to 40%

- Optimize your cutting parameters through real-time monitoring and adjustment of speed, power, and focal length

- Implement predictive maintenance protocols to minimize unexpected downtime and extend equipment life

- Utilize advanced nesting software to maximize material utilization and reduce waste by up to 25%

Future Trends and Technological Advancements

Building on these industry achievements, emerging innovations in tube laser cutting technology point toward a transformative future. You’ll witness significant advancements in sustainability trends y automation integration that’ll reshape manufacturing processes.

- Advanced AI-driven control systems will optimize cutting patterns and material usage, reducing waste by up to 40% while maintaining precision within 0.1mm tolerances

- Smart sensors and predictive maintenance algorithms will detect potential failures before they occur, increasing uptime to 98%

- Automation integration will enable lights-out manufacturing with robotic material handling and seamless ERP connectivity

- Green technologies like fiber lasers will reduce energy consumption by 70% while implementing closed-loop water cooling systems

These developments aren’t just theoretical – they’re already being implemented in next-generation tube laser cutting systems, positioning you at the forefront of manufacturing innovation.

Conclusión

Verá que tube laser cutting technology isn’t just transforming manufacturing – it’s redefining what’s possible in precision engineering. Through empirical analysis, the theory that integrated CAD/CAM systems coupled with advanced laser optics can achieve sub-0.1mm tolerances has been validated across multiple industrial applications. Your production efficiency can increase by 40-60% while maintaining dimensional accuracy, suggesting this technology will become the new standard in tube processing.