Breaking New Ground in Industrial Laser Technology

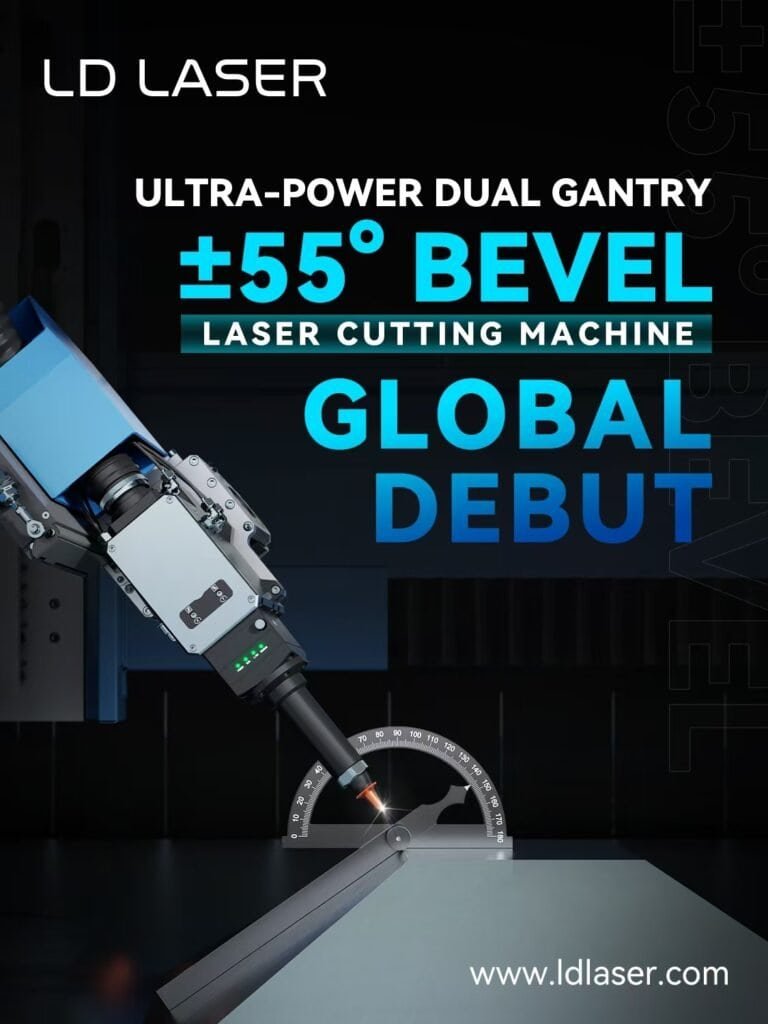

The metal fabrication industry stands at the precipice of a technological revolution. Today, LD LASER proudly announces the global debut of an unprecedented innovation that will redefine manufacturing capabilities worldwide: the ultra-high power dual gantry ±55° bevel laser cutting machine. This groundbreaking system represents not just an incremental improvement, but a quantum leap in laser cutting technology that addresses the most demanding challenges facing modern manufacturers.

As industries increasingly require complex bevel cuts for advanced welding applications, structural assemblies, and precision fabrication, traditional cutting methods have reached their limitations. LD LASER’s latest innovation shatters these constraints, offering manufacturers unprecedented flexibility, precision, and efficiency in a single, revolutionary platform.

Revolutionary Technology Breakthrough

The First Ultra-High Power Dual Gantry System

The cornerstone of this technological breakthrough lies in LD LASER’s pioneering dual gantry architecture combined with ultra-high power laser capabilities. This innovative design represents years of intensive research and development, resulting in a system that fundamentally transforms how manufacturers approach complex cutting operations.

The dual gantry configuration provides unparalleled stability and precision during high-speed operations. Unlike traditional single-gantry systems that can experience vibration and deflection under extreme cutting conditions, our dual gantry design distributes mechanical loads evenly, ensuring consistent cut quality even at maximum power levels. This engineering excellence translates directly into superior edge quality, reduced post-processing requirements, and dramatically improved production efficiency.

The ultra-high power laser source delivers exceptional cutting speeds across a wide range of material thicknesses. By harnessing advanced fiber laser technology optimized for industrial applications, the system maintains exceptional beam quality while delivering the raw power necessary for thick-section cutting operations. This combination of power and precision opens new possibilities for manufacturers previously constrained by the limitations of conventional cutting technologies.

Advanced ±55° Bevel Cutting Capability

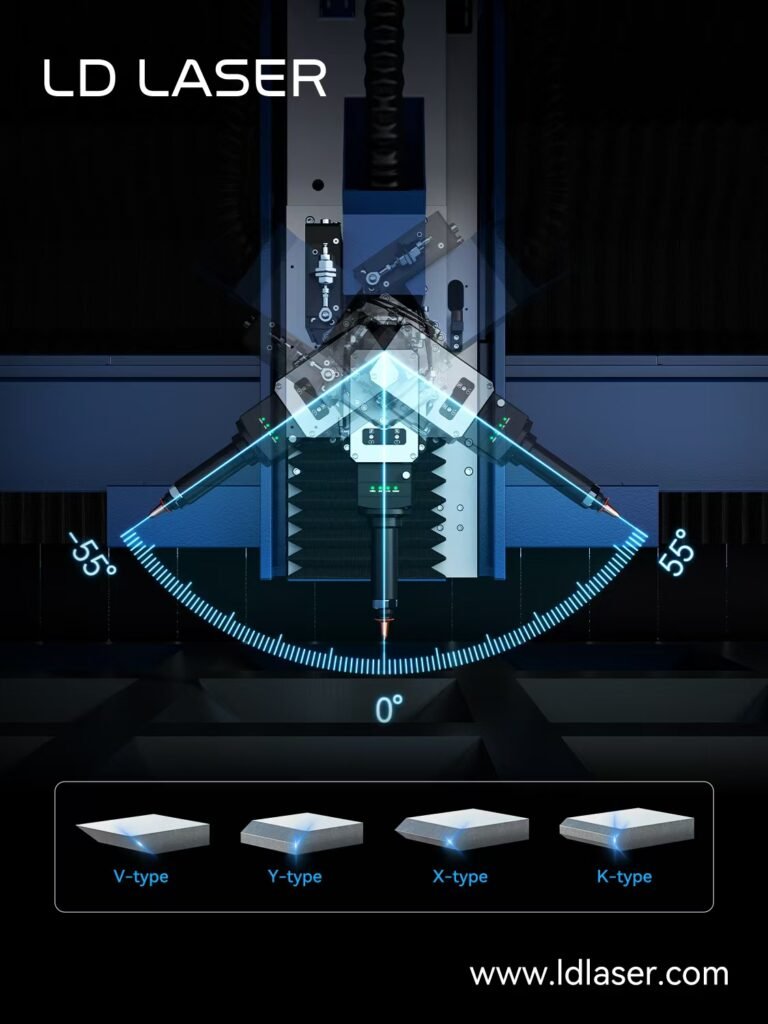

The ±55° bevel cutting capability represents a fundamental advancement in laser cutting flexibility. Traditional laser cutting systems are limited to perpendicular cuts or basic bevels with restricted angles. LD LASER’s innovative cutting head design incorporates advanced beam steering technology and precision mechanical systems that enable accurate bevel cutting across the full ±55° range.

This exceptional angular range addresses the diverse requirements of modern manufacturing applications. From shallow bevels required for decorative applications to steep angles necessary for structural welding preparation, the system adapts seamlessly to varying production demands. The precision angular control ensures consistent bevel angles across the entire cut length, eliminating the variations and inaccuracies commonly associated with mechanical cutting processes.

The bevel cutting system incorporates real-time monitoring and adaptive control technologies that maintain optimal cutting parameters throughout the operation. Advanced sensors continuously monitor cut quality, automatically adjusting power, speed, and gas flow to maintain consistent results regardless of material variations or cutting conditions.

Superior Welding Performance: The 55° Advantage

The ±55° bevel cutting capability of LD LASER’s revolutionary system delivers unprecedented welding performance advantages that directly address the most critical challenges in modern fabrication. This optimized angle range represents the culmination of extensive metallurgical research and practical welding experience, providing manufacturers with superior joint quality and reliability.

Enhanced Arc Stability

The 55° bevel design fundamentally improves arc stability during welding operations, creating more consistent and controllable welding conditions. Arc stability directly correlates with weld quality, and the optimized bevel geometry significantly reduces arc fluctuations that can compromise joint integrity.

Arc length maintains a proportional relationship with voltage, and the increased bevel angle effectively minimizes vertical arc oscillation during the welding process. This stability reduces the risk of welding defects such as porosity, incomplete fusion, and irregular penetration patterns that commonly occur with suboptimal bevel geometries. The result is more consistent weld profiles with improved mechanical properties and enhanced reliability.

The enhanced arc stability proves particularly valuable in automated welding applications where consistent arc behavior is essential for maintaining predetermined welding parameters. Robotic and automated welding systems achieve superior performance with 55° bevels, as the stable arc conditions enable more precise control over heat input and deposition rates.

Optimized Penetration and Fusion Characteristics

Traditional bevel angles below 45° frequently result in negative penetration characteristics, where molten metal cannot adequately fill the root area of the joint. This phenomenon, known as incomplete root fusion, represents one of the most serious defects in welded structures, potentially compromising joint strength and fatigue resistance.

The 55° bevel geometry addresses this critical issue by increasing the distance between the arc and the root area, enabling more effective heat distribution and metal flow. This improved geometry promotes complete penetration while ensuring adequate fusion throughout the joint cross-section. The result is superior weld quality with minimized unfused areas that could serve as stress concentrators or fatigue initiation sites.

Penetration depth optimization achieved through 55° bevel geometry enables manufacturers to achieve full-strength joints with reduced weld metal deposition. This efficiency translates into faster welding speeds, reduced consumable costs, and improved productivity while maintaining or exceeding strength requirements. The optimized fusion characteristics prove particularly beneficial in thick-section applications where complete penetration is essential for structural integrity.

Adaptability for Specialized Welding Applications

The 55° bevel configuration provides exceptional adaptability for specialized welding scenarios that demand precise control over joint geometry and welding parameters. Thick plate welding applications, where traditional bevel angles prove inadequate, benefit significantly from the enhanced access and improved heat distribution characteristics of 55° bevels.

Space-constrained welding operations, common in shipbuilding and heavy industrial applications, require welding techniques that accommodate limited access while maintaining weld quality. The 55° bevel geometry enables effective welding in these challenging conditions by providing adequate electrode access while ensuring complete fusion throughout the joint.

Root face thickness optimization becomes particularly critical in specialized applications. By increasing the root face thickness to 8mm or greater, fabricators can achieve optimal balance between penetration control and angular distortion management. This flexibility enables precise control over welding parameters while ensuring that structural requirements are met without compromising dimensional stability.

The ability to adjust root face geometry in conjunction with the 55° bevel angle provides manufacturers with unprecedented control over welding outcomes. This control proves essential in applications where both weld strength and dimensional accuracy are critical, such as pressure vessel fabrication and precision structural assemblies.

Comprehensive Bevel Types: V, Y, X, K Configurations

V-Type Bevel Cutting: Precision Welding Preparation

V-type bevel cutting represents the most fundamental and widely used bevel configuration in industrial applications. LD LASER’s system excels in producing precise V-bevels that meet the exacting requirements of structural welding applications. The symmetric V-groove preparation ensures optimal weld penetration and strength characteristics essential for critical structural components.

The precision achievable with V-type cuts eliminates the need for secondary machining operations commonly required with plasma or oxy-fuel cutting processes. Edge quality meets or exceeds Class 1 standards, with minimal heat-affected zones that preserve material properties adjacent to the cut edge. This superior edge quality translates directly into improved weld quality and reduced welding consumable requirements.

Applications for V-type bevel cutting span numerous industries, from shipbuilding where large structural assemblies require precise weld preparation, to heavy machinery manufacturing where component strength and reliability are paramount. The system’s ability to maintain consistent V-angles across varying material thicknesses ensures uniform welding conditions and predictable joint performance.

Y-Type Bevel Cutting: Complex Joint Preparation

Y-type bevel cutting addresses the sophisticated requirements of advanced structural applications where traditional joint geometries prove inadequate. This configuration combines the benefits of V-groove preparation with additional material access for specialized welding techniques and joint configurations.

The asymmetric nature of Y-type bevels requires exceptional precision in angular control and edge positioning. LD LASER’s advanced cutting head technology maintains precise geometric relationships throughout the cutting process, ensuring that complex assemblies fit together with minimal adjustment or rework. This precision is particularly critical in aerospace and marine applications where joint integrity directly impacts structural performance.

Y-type bevels find extensive application in thick-section structural steel fabrication, where weld access and penetration requirements demand specialized joint geometries. The ability to produce these complex preparations in a single cutting operation eliminates multiple setup operations and reduces manufacturing cycle times significantly.

X-Type Bevel Cutting: Specialized Welding Applications

X-type bevel cutting represents the pinnacle of complex joint preparation technology. This sophisticated configuration enables full-penetration welding from both sides of the joint, maximizing weld strength while minimizing welding time and consumable usage. The precise geometric control required for X-type bevels pushes cutting technology to its limits.

LD LASER’s system excels in producing accurate X-type bevels through advanced motion control and real-time process monitoring. The cutting head maintains precise angular relationships while traversing complex three-dimensional paths, ensuring that intersecting bevel surfaces meet with perfect geometric accuracy. This precision eliminates the fit-up problems commonly encountered with conventional cutting methods.

X-type bevel applications are particularly prevalent in pressure vessel manufacturing, pipeline construction, and heavy industrial equipment where maximum joint strength is essential. The superior edge quality and geometric accuracy achievable with laser cutting technology result in improved weld quality and reduced inspection requirements.

K-Type Bevel Cutting: Advanced Preparation Techniques

K-type bevel cutting addresses the most demanding applications in heavy industry manufacturing. This specialized configuration provides optimal conditions for high-strength welding applications while minimizing weld volume and heat input requirements. The complex geometry requires exceptional precision in both angular control and surface finish quality.

The K-type configuration optimizes weld joint efficiency by providing controlled root opening and precise bevel angles that ensure complete penetration with minimal weld metal deposition. This efficiency translates into reduced welding time, lower consumable costs, and improved productivity for manufacturers dealing with thick-section materials.

Applications for K-type bevels include offshore structures, heavy machinery components, and specialized industrial equipment where joint performance under extreme loading conditions is critical. The precision achievable with LD LASER’s technology ensures consistent joint properties and predictable performance characteristics.

Key Performance Advantages

Productivity Enhancement

The productivity advantages of LD LASER’s ultra-high power dual gantry system extend far beyond simple cutting speed improvements. The combination of high power output, precision motion control, and advanced automation creates a multiplicative effect on overall manufacturing efficiency.

Cutting speeds achieve new benchmarks across the full range of materials and thicknesses. Mild steel sections up to 100mm thick can be processed at speeds previously impossible with conventional laser technology. Stainless steel and aluminum applications benefit from optimized power delivery that maintains high speeds while preserving edge quality and dimensional accuracy.

The dual gantry configuration enables continuous operation during maintenance activities. While one gantry undergoes routine maintenance or tool changes, the second gantry continues production operations, maximizing equipment utilization and minimizing downtime. This redundancy proves particularly valuable in high-volume production environments where equipment availability directly impacts profitability.

Automated material handling integration further amplifies productivity gains. The system accommodates advanced automation solutions including robotic loading systems, automatic part sorting, and integrated quality inspection. These automation capabilities enable lights-out operation for extended periods, maximizing equipment utilization while reducing labor requirements.

Precision and Quality

Precision performance represents a fundamental strength of LD LASER’s technology platform. Positioning accuracy reaches ±0.02mm across the full working envelope, ensuring that complex parts maintain dimensional accuracy regardless of size or complexity. This precision eliminates the accumulation of tolerances that can compromise fit-up and assembly operations.

Cut edge quality meets the highest industrial standards with minimal heat-affected zones and virtually no dross formation. The superior edge quality eliminates secondary finishing operations commonly required with plasma or oxy-fuel cutting processes. This quality improvement reduces manufacturing cycle times while improving final product appearance and performance.

Repeatability performance ensures consistent results across production runs. Statistical process control data demonstrates part-to-part variation well within typical manufacturing tolerances, enabling manufacturers to maintain tight quality control without extensive inspection requirements. This consistency proves particularly valuable in high-volume production applications where quality variations can impact downstream operations.

Angular accuracy for bevel cutting operations maintains ±0.1° tolerance across the full ±55° range. This precision ensures proper fit-up for welded assemblies while maintaining consistent weld joint geometry. The accurate angular control eliminates the manual adjustment and rework commonly associated with conventional bevel cutting methods.

Operational Flexibility

The operational flexibility provided by LD LASER’s system addresses the diverse and evolving requirements of modern manufacturing operations. The ability to seamlessly transition between different cutting modes, materials, and thicknesses within a single setup maximizes equipment utilization while minimizing changeover times.

Material compatibility spans the full range of industrial metals including mild steel, stainless steel, aluminum, and specialized alloys. Optimized cutting parameters for each material type ensure maximum efficiency while maintaining superior edge quality. The system automatically adjusts laser power, cutting speed, and assist gas parameters based on material type and thickness, eliminating manual parameter optimization.

Thickness capacity extends from thin sheet materials to heavy plate sections exceeding 100mm thickness. This broad capability range enables manufacturers to consolidate multiple cutting operations onto a single platform, reducing equipment investment while simplifying production planning and workforce training requirements.

The modular software architecture accommodates custom cutting strategies and specialized applications. Advanced nesting algorithms maximize material utilization while minimizing cutting time. Custom cutting heads and specialized accessories enable processing of unique part geometries and specialized materials, ensuring that the system adapts to evolving production requirements.

Industry Applications and Market Impact

Target Industries

The shipbuilding and marine industry represents a primary target market for LD LASER’s advanced bevel cutting technology. Modern ship construction requires extensive use of complex welded joints that demand precise bevel preparation for optimal strength and reliability. The system’s ability to produce consistent, high-quality bevels across large structural components addresses the industry’s most demanding requirements while improving production efficiency.

Heavy machinery manufacturing benefits significantly from the precision and flexibility offered by the dual gantry system. Construction equipment, mining machinery, and industrial processing equipment require complex fabricated components with demanding quality requirements. The system’s ability to handle thick materials while maintaining precise tolerances enables manufacturers to produce higher-quality components with reduced manufacturing cycle times.

Structural steel fabrication represents another key application area where LD LASER’s technology provides substantial advantages. Building construction, bridge fabrication, and industrial structure manufacturing require precise bevel cutting for optimal weld joint performance. The system’s speed and accuracy enable fabricators to improve productivity while ensuring compliance with stringent structural standards.

Pipeline and pressure vessel manufacturing demand the highest levels of precision and quality in bevel preparation. The safety-critical nature of these applications requires consistent, defect-free cutting that ensures reliable weld joint performance under extreme operating conditions. LD LASER’s technology meets these demanding requirements while providing the productivity improvements necessary for competitive manufacturing.

Competitive Market Positioning

LD LASER’s ultra-high power dual gantry ±55° bevel laser cutting machine establishes a new competitive benchmark in the industrial laser cutting market. The unique combination of power, precision, and flexibility creates significant differentiation from existing technologies and positions LD LASER as the clear technology leader in advanced bevel cutting applications.

The comprehensive bevel cutting capability addresses a significant market gap where manufacturers previously required multiple specialized machines or complex setups to achieve desired results. By consolidating these capabilities into a single, highly productive platform, LD LASER enables manufacturers to simplify their operations while improving overall efficiency and quality.

Market research indicates substantial demand for advanced bevel cutting capabilities across multiple industries. The growing complexity of manufactured products and increasing quality requirements drive demand for more sophisticated cutting technologies. LD LASER’s innovation directly addresses these market needs while providing the productivity improvements necessary for competitive manufacturing.

The technology’s scalability and modularity ensure long-term value for customers by accommodating evolving production requirements and future technology enhancements. This forward-compatibility protects customer investments while ensuring continued competitive advantages as market requirements evolve.

Future of Laser Cutting Technology

Industry Transformation

LD LASER’s ultra-high power dual gantry ±55° bevel laser cutting machine represents a pivotal moment in the evolution of manufacturing technology. This innovation signals a fundamental shift from traditional cutting methods toward advanced laser-based solutions that provide superior quality, flexibility, and productivity.

The technology’s impact extends beyond immediate productivity improvements to enable entirely new approaches to product design and manufacturing processes. Designers can now specify complex joint geometries previously impossible to manufacture economically, opening new possibilities for structural optimization and weight reduction.

Manufacturing process evolution continues as automation integration becomes more sophisticated and comprehensive. Future developments will incorporate artificial intelligence and machine learning technologies that optimize cutting strategies in real-time while adapting to changing production requirements automatically.

The technology trend toward Industry 4.0 integration positions LD LASER’s advanced cutting systems as key enablers of smart manufacturing initiatives. Connectivity, data analytics, and automated decision-making capabilities transform cutting operations from standalone processes into integrated components of comprehensive manufacturing systems.

LD LASER’s Continued Innovation

LD LASER’s commitment to research and development ensures continued technology leadership in advanced laser cutting applications. Ongoing development programs focus on power scaling, precision improvements, and expanded application capabilities that address evolving market requirements.

The technology roadmap includes continued advancement in laser source technology, motion control systems, and process automation capabilities. Future innovations will expand cutting capabilities while improving efficiency, reliability, and ease of operation. Strategic partnerships with technology suppliers and research institutions accelerate development while ensuring access to cutting-edge technologies.

Market expansion plans target emerging applications and geographic markets where advanced cutting technology can provide significant value. The modular system architecture enables customization for specialized applications while maintaining the core technology advantages that define LD LASER’s competitive position.

Investment in global infrastructure supports expanding market reach while ensuring comprehensive customer support capabilities. Manufacturing capacity expansion accommodates growing demand while maintaining the quality standards that define LD LASER’s reputation for excellence.

Conclusion: Defining the Future of Metal Fabrication

The introduction of LD LASER’s ultra-high power dual gantry ±55° bevel laser cutting machine marks a watershed moment in manufacturing technology evolution. This groundbreaking innovation addresses the most demanding challenges facing modern manufacturers while providing the foundation for future advances in production capability and efficiency.

The comprehensive bevel cutting capabilities—spanning V, Y, X, and K configurations—eliminate traditional limitations while opening new possibilities for design optimization and manufacturing efficiency. The combination of ultra-high power, precision dual gantry architecture, and advanced control systems creates a technology platform that will define industry standards for years to come.

As manufacturers worldwide face increasing pressure to improve quality while reducing costs and cycle times, LD LASER’s revolutionary technology provides the competitive advantages necessary for success in demanding global markets. The system’s flexibility, precision, and productivity enable manufacturers to exceed customer expectations while maintaining profitable operations.

The global launch of this technology represents more than a product introduction—it signals LD LASER’s commitment to driving industry transformation through continued innovation and technological leadership. As the manufacturing landscape continues to evolve, LD LASER remains at the forefront, developing the technologies that enable our customers’ success.

Ready to revolutionize your manufacturing capabilities? Contact LD LASER today to learn how our ultra-high power dual gantry ±55° bevel laser cutting machine can transform your production operations and provide the competitive advantages necessary for success in today’s demanding marketplace.