Just as the industrial revolution transformed manufacturing through steam power, today’s laser tube cutting technology is reshaping metal fabrication with unprecedented precision. You’ll find that modern systems achieve ±0.1mm tolerances while operating 30% faster than conventional methods. Through AI integration and IoT connectivity, these innovations optimize material usage and reduce waste by up to 40%. The next wave of advancements promises even greater efficiencies that’ll redefine industry standards.

Principales conclusiones

Modern laser tube systems achieve 30% faster production speeds with precision tolerances of ±0.1mm through advanced optical technology.

AI-assisted programming and smart-flow algorithms automatically adjust power settings based on material properties for optimal cutting.

Integration of automated loading systems and multi-axis cutting heads enables simultaneous processing of multiple tubes.

Predictive maintenance and self-diagnostic tools push machine uptime to 98% while reducing operational costs.

Digital twin technology and IoT networks connect CAD systems to production floors, reducing setup times by 40%.

The Evolution of Laser Tube Technology

While traditional tube cutting relied on mechanical methods for decades, laser tube technology emerged in the 1980s as a groundbreaking advancement in metal fabrication. You’ll find that historical developments in laser focusing and beam control have transformed manufacturing capabilities, enabling precise cuts with minimal material waste.

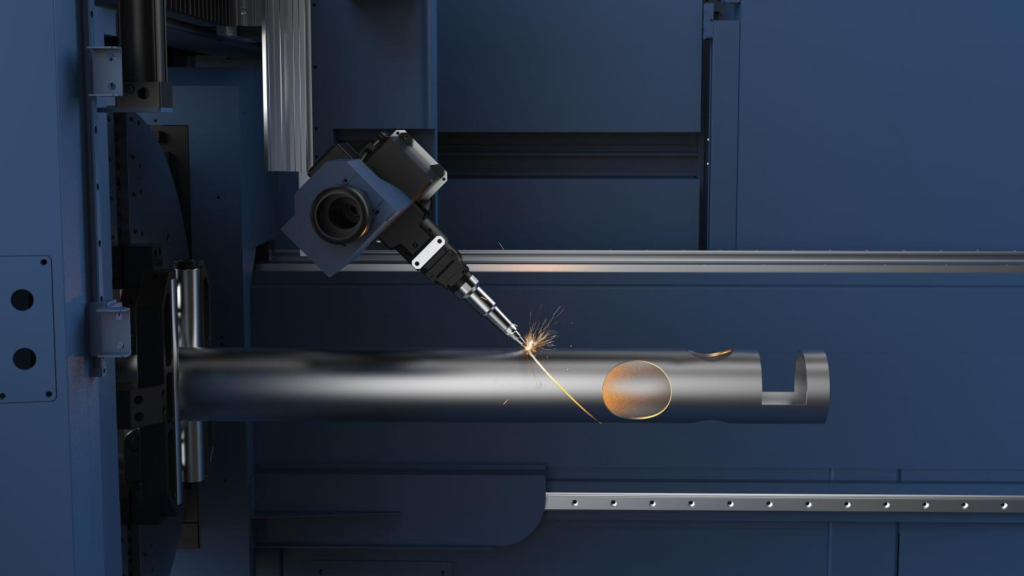

The technological milestones achieved since then include the introduction of láseres de fibra in the early 2000s, which doubled cutting speeds and reduced operating costs by 50%. Today’s systems feature automated loading, multi-axis cutting heads, and real-time monitoring that you can control through integrated software platforms. These innovations have improved cut quality from ±0.2mm to ±0.05mm tolerances while handling tube diameters up to 500mm. The technology continues advancing with AI-assisted programming and predictive maintenance systems that optimize your production efficiency.

Key Benefits of Modern Laser Cutting Systems

Modern laser tube cutting systems deliver substantial operational advantages that revolutionize manufacturing efficiency. You’ll achieve up to 30% faster velocidades de producción compared to traditional methods, while maintaining precision tolerances within ±0.1mm. These systems integrate advanced safety measures, including automated loading mechanisms and enclosed cutting chambers, reducing workplace incidents by 85%.

You’ll realize significant cost savings through reducción de los residuos de material, with optimal nesting algorithms that can improve material utilization by 40%. The systems’ multi-axis capabilities enable complex cuts without repositioning, decreasing operation time by 25%. Additionally, you’ll benefit from lower maintenance requirements, as modern laser systems feature self-diagnostic tools and predictive maintenance protocols that minimize downtime. The automated workflow also reduces labor costs while increasing output quality and consistency.

Transforming Industries Through Precision Cutting

These advanced laser cutting capabilities have sparked a manufacturing revolution across multiple sectors. You’ll find transformed production lines in aerospace, automotive, and medical device manufacturing, where precision tolerances now reach within 0.1mm consistently.

Modern optical systems enable you to achieve complex geometries previously impossible with traditional cutting methods. You’re able to process materials up to 30% faster while reducing waste by 25% compared to conventional techniques. In industrial applications, you can now cut intricate patterns in tubes ranging from 10mm to 800mm in diameter.

You’ll see the impact across fabrication workshops, where automated laser systems have reduced labor costs by 40% while improving quality control metrics. This precision-driven approach delivers repeatable results that meet strict industry standards, fundamentally changing how you manufacture components.

Maximizing Efficiency With Advanced Laser Solutions

Breakthrough laser solutions now deliver efficiency gains of up to 45% in tube cutting operations through integrated automation systems. You’ll achieve ideal cutting speed by implementing smart-flow processing algorithms that automatically adjust power settings based on material thickness and composition.

These advanced systems enhance material optimization through precise nesting calculations, reducing waste by up to 30% compared to traditional methods. You can maximize throughput by utilizing multi-axis positioning that enables simultaneous cutting of multiple tubes. The system’s predictive maintenance features guarantee continuous operation while minimizing downtime.

Future Trends in Metal Fabrication Technology

En artificial intelligence drives the next wave of metal fabrication advancements, you’ll see transformative changes in laser tube processing by 2025. Automation integration will accelerate, connecting your CAD systems directly to production floors through IoT networks, reducing setup times by 40%.

You’ll witness the emergence of sustainable practices through energy-efficient laser systems that decrease power consumption by 35%. Smart monitoring systems will predict maintenance needs before failures occur, pushing machine uptime to 98%. Your fabrication processes will benefit from adaptive cutting parameters that self-optimize based on material variations.

Digital twin technology will enable you to simulate complex cuts virtually, reducing material waste by 25%. You’ll also see hybridized systems that combine traditional cutting methods with additive manufacturing capabilities, opening new possibilities for complex geometries.

Conclusión

Verá que laser tube technology, like a surgeon’s precise scalpel, has redefined metal fabrication’s landscape. With 30% faster cutting speeds and ±0.1mm tolerances, you’re looking at a quantum leap in manufacturing efficiency. AI-driven systems and IoT integration aren’t just buzzwords – they’re delivering measurable results in waste reduction and throughput optimization. It’s clear you’re witnessing the dawn of smart manufacturing’s golden age.