Revolutionizing Industrial Fabrication Through Advanced Automation

The manufacturing landscape stands at a transformative crossroads where traditional welding processes give way to revolutionary automation technologies. As industries worldwide grapple with skilled labor shortages, increasing quality demands, and relentless pressure for productivity improvements, the need for intelligent welding solutions has never been more critical. LD LASER proudly introduces the future of automated manufacturing: the 7-Axis Intelligent Welding Robot Station, a groundbreaking system that redefines what’s possible in industrial fabrication.

This advanced robotic welding platform represents more than an evolutionary step—it embodies a quantum leap in manufacturing capability. By combining unprecedented mechanical flexibility with artificial intelligence and Industry 4.0 connectivity, our 7-axis system addresses the most complex welding challenges while delivering the consistency, quality, and efficiency that modern manufacturing demands.

Traditional welding operations, constrained by human limitations and conventional automation boundaries, struggle to meet the increasingly sophisticated requirements of contemporary manufacturing. Complex geometries, demanding quality standards, and the need for 24/7 production capability expose the limitations of conventional approaches. LD LASER’s intelligent welding robot station eliminates these constraints, opening new possibilities for design innovation and manufacturing excellence.

Revolutionary 7-Axis Technology

Advanced Motion Capabilities

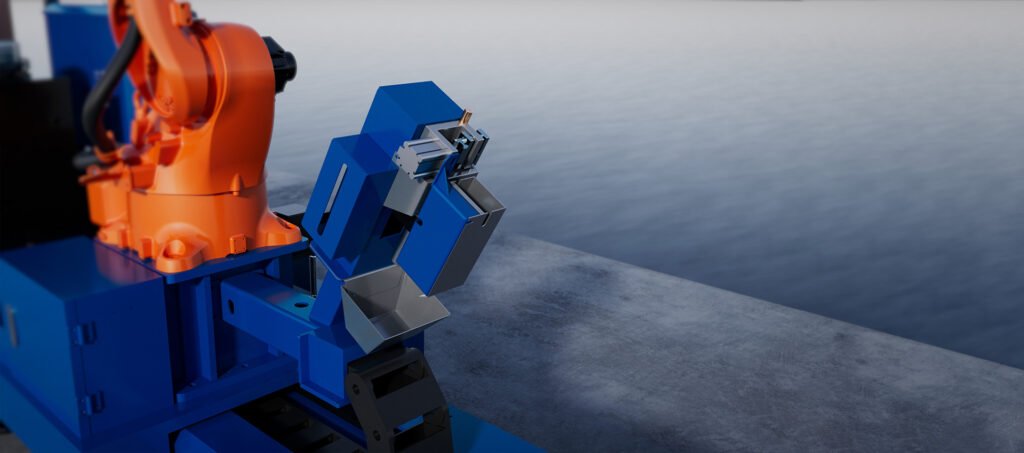

The cornerstone of LD LASER’s welding robot station lies in its revolutionary 7-axis configuration, which fundamentally transforms welding accessibility and precision. Unlike traditional 6-axis systems that often struggle with complex geometries and restricted access situations, the additional axis provides unprecedented flexibility for navigating intricate workpieces and challenging welding positions.

The extended reach capability enables welding operations in previously inaccessible areas, eliminating the need for complex fixturing or workpiece repositioning. This enhanced accessibility proves particularly valuable in large assemblies where conventional robots cannot maintain optimal welding positions throughout the entire operation. The seventh axis acts as a linear extension that positions the robot optimally relative to the workpiece, ensuring consistent welding parameters regardless of part size or complexity.

Complex geometry welding solutions become achievable through the system’s advanced kinematics. Internal corners, deep recesses, and multi-plane joints that once required manual welding or multiple robot setups can now be completed in single operations. This capability dramatically reduces manufacturing cycle times while improving weld quality consistency across complex assemblies.

Multi-angle positioning precision ensures optimal torch orientation for every welding situation. The system automatically calculates and maintains ideal travel angles, work angles, and standoff distances throughout the welding process. This precision eliminates the compromises inherent in fixed-position welding while ensuring optimal penetration, fusion, and mechanical properties in every joint.

Workspace optimization benefits extend beyond simple reach improvements to encompass intelligent path planning and collision avoidance. The system’s advanced motion control algorithms calculate optimal welding sequences that minimize travel time while ensuring accessibility to all required joints. This optimization proves particularly valuable in high-volume production where cycle time improvements translate directly into productivity gains.

Intelligent Control Systems

The integration of artificial intelligence transforms welding from a largely empirical process into a data-driven, optimized operation. LD LASER’s intelligent control systems continuously monitor welding parameters and automatically adjust settings to maintain optimal conditions throughout the entire operation. This real-time optimization eliminates the variations inherent in manual welding while adapting to changing conditions that would challenge even experienced operators.

AI-powered welding parameter optimization analyzes multiple inputs including material properties, joint geometry, environmental conditions, and quality requirements to determine optimal welding settings. The system’s machine learning algorithms continuously refine these parameters based on real-world performance data, ensuring that welding quality improves over time as the system gains experience with specific applications.

Real-time adaptive control technology monitors arc characteristics, penetration depth, and bead formation during welding operations. Advanced sensors provide continuous feedback on welding conditions, enabling immediate parameter adjustments when deviations occur. This responsiveness ensures consistent quality even when material properties vary or environmental conditions change.

Machine learning integration enables the system to recognize patterns and predict optimal welding strategies for new applications based on previous experience. The system builds a comprehensive knowledge base of successful welding parameters and techniques, enabling rapid optimization for new parts and materials without extensive trial-and-error development.

Predictive process adjustment capabilities anticipate welding challenges before they occur. By analyzing sensor data trends and comparing them with historical patterns, the system can adjust parameters proactively to prevent defects and maintain quality consistency. This predictive capability minimizes waste while ensuring that production targets are met consistently.

Superior Flexibility vs. Traditional Systems

The advantages of 7-axis configuration become apparent when compared directly with conventional 6-axis welding robots. Traditional systems often require complex workpiece positioning or multiple robot installations to achieve complete weld access on complex assemblies. The additional axis eliminates these limitations, providing complete flexibility for welding operations regardless of part geometry or size constraints.

Enhanced wrist articulation provided by the seventh axis enables optimal torch positioning even in constrained spaces. The system can maintain ideal welding angles while navigating around obstacles that would prevent conventional robots from accessing required joints. This articulation proves particularly valuable in automotive body welding, structural fabrication, and complex assembly operations.

Obstacle avoidance capabilities integrated into the motion control system enable safe operation in cluttered work environments. The system automatically calculates collision-free paths while maintaining optimal welding positions, eliminating the programming complexity typically associated with complex welding sequences. This capability enables efficient operation in production environments where space constraints limit conventional automation approaches.

Complex part accessibility expands the range of applications suitable for robotic welding. Parts with deep recesses, internal structures, or multi-level assemblies that previously required manual welding can now be automated effectively. This expanded capability enables manufacturers to achieve automation benefits across their entire product range rather than limiting automation to simple, easily accessible applications.

Smart Manufacturing Integration

Industry 4.0 Connectivity

LD LASER’s 7-Axis Intelligent Welding Robot Station exemplifies Industry 4.0 principles through comprehensive connectivity and data integration capabilities. The system seamlessly integrates with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms, providing real-time production data and enabling coordinated manufacturing operations across multiple production lines.

IoT sensor integration provides comprehensive monitoring of welding operations and system performance. Temperature sensors, current monitors, gas flow meters, and vibration sensors continuously collect data that enables detailed analysis of welding processes and equipment performance. This sensor network provides the foundation for predictive maintenance, quality assurance, and process optimization initiatives.

Real-time data analytics transform raw sensor data into actionable insights for production optimization. Advanced analytics algorithms identify trends, predict quality issues, and recommend process improvements based on comprehensive analysis of welding performance data. This intelligence enables continuous improvement initiatives that enhance productivity while maintaining quality standards.

Cloud-based monitoring systems enable remote access to production data and system performance metrics. Manufacturing engineers and management can monitor operations from any location while accessing historical data for trend analysis and performance optimization. This connectivity proves particularly valuable for multi-site operations where centralized monitoring improves efficiency and consistency.

Remote diagnostics and control capabilities enable immediate response to system issues regardless of location. LD LASER’s technical support team can access system diagnostics remotely, often resolving issues without on-site visits. This capability minimizes downtime while ensuring that customers receive immediate support when needed.

Production Line Integration

Seamless workflow automation capabilities enable the welding robot station to integrate effectively with existing production lines and manufacturing systems. The system communicates with upstream and downstream processes to coordinate material flow, optimize production scheduling, and ensure smooth operations across the entire manufacturing sequence.

Multi-station coordination enables multiple welding robots to work collaboratively on large assemblies or high-volume production operations. Advanced scheduling algorithms optimize workload distribution among multiple stations while ensuring that quality standards are maintained consistently. This coordination capability proves particularly valuable in automotive manufacturing and other high-volume applications.

Quality management systems integration provides comprehensive traceability and documentation for every welding operation. The system automatically records welding parameters, quality measurements, and process data for each part, creating detailed records that support quality assurance and regulatory compliance requirements. This documentation capability proves essential in industries with stringent quality requirements.

Material handling integration enables automated loading and unloading of workpieces, further enhancing productivity and reducing labor requirements. The system coordinates with conveyor systems, automated guided vehicles (AGVs), and robotic material handling equipment to create fully automated production cells that operate with minimal human intervention.

Digital Twin Technology

Virtual commissioning capabilities enable complete system testing and optimization before physical installation. Digital twin technology creates accurate virtual representations of the welding robot station and its operating environment, enabling comprehensive testing of welding programs and optimization of cycle times before production begins. This virtual commissioning reduces startup time while ensuring optimal performance from day one.

Process simulation and optimization tools enable detailed analysis of welding operations and identification of improvement opportunities. Engineers can test different welding sequences, parameter settings, and tooling configurations virtually, optimizing performance without disrupting production operations. This simulation capability proves particularly valuable for complex applications where optimization requires extensive testing.

Predictive maintenance planning utilizes digital twin models to simulate equipment wear and predict maintenance requirements. By analyzing operating conditions and usage patterns, the system can schedule maintenance activities optimally to minimize production disruptions while ensuring equipment reliability. This predictive approach reduces maintenance costs while improving equipment availability.

Performance monitoring and analysis capabilities provide continuous comparison between actual operations and digital twin predictions. This comparison enables continuous refinement of virtual models while identifying opportunities for performance improvements. The ongoing correlation between virtual and actual performance ensures that digital twin models remain accurate and useful throughout the equipment lifecycle.

Intelligent Features and Capabilities

Adaptive Welding Technology

Advanced seam tracking and guidance systems represent a fundamental breakthrough in welding automation. LD LASER’s intelligent welding robot incorporates sophisticated vision systems and laser tracking technology that continuously monitor joint geometry and automatically adjust welding parameters to maintain optimal conditions. This adaptive capability eliminates the precision requirements typically associated with robotic welding while ensuring consistent quality regardless of part variations.

The seam tracking system utilizes advanced laser sensors to map joint geometry in real-time, automatically compensating for part variations, thermal distortion, and fixture positioning errors. This capability enables successful welding operations even when parts don’t match CAD specifications exactly, dramatically improving first-pass success rates while reducing the precision requirements for upstream manufacturing processes.

Automatic parameter adjustment responds instantaneously to changing welding conditions. When the system detects variations in gap width, material thickness, or joint geometry, it automatically adjusts welding current, travel speed, and wire feed rate to maintain optimal welding conditions. This responsiveness ensures consistent penetration and fusion characteristics regardless of part variations that would challenge conventional robotic welding systems.

Gap and mismatch compensation capabilities address real-world manufacturing variations that often prevent successful automation of welding operations. The system can accommodate significant gaps between parts while maintaining weld quality through automatic adjustment of welding parameters and oscillation patterns. This tolerance for part variations enables successful automation of applications previously requiring manual welding due to fit-up challenges.

Material thickness adaptation enables the system to weld parts with varying cross-sections without reprogramming. Advanced sensors continuously monitor material thickness and automatically adjust penetration control parameters to ensure complete fusion without burn-through. This capability proves particularly valuable in applications involving tapered sections or parts with varying wall thicknesses.

Quality Assurance Systems

In-process monitoring and inspection capabilities provide real-time quality control that surpasses traditional post-weld inspection methods. Advanced sensor systems continuously monitor arc characteristics, penetration depth, and bead formation during welding operations, providing immediate feedback on weld quality. This real-time monitoring enables immediate corrective action when quality issues are detected, preventing defective parts from progressing through production.

Defect detection and correction systems identify potential quality issues before they become serious problems. Machine learning algorithms analyze sensor data to recognize patterns associated with porosity, incomplete fusion, or other weld defects, automatically adjusting parameters to prevent defect formation. When defects are detected, the system can automatically stop welding and alert operators or initiate corrective procedures.

Statistical process control integration provides comprehensive documentation of welding quality trends and enables proactive quality management. The system continuously collects quality data and performs statistical analysis to identify trends that might indicate process drift or equipment issues. This statistical approach enables preventive action before quality problems affect production output.

Automated quality reporting generates comprehensive documentation of welding quality for every part produced. The system automatically creates quality certificates, inspection reports, and traceability documentation that support regulatory compliance and customer quality requirements. This automated documentation eliminates manual inspection and reporting tasks while ensuring complete quality records.

Programming and Operation

Intuitive teach pendant interface design enables operators to program complex welding operations without extensive robotics expertise. The user-friendly interface guides operators through welding program development using graphical representations and step-by-step procedures that simplify complex programming tasks. This accessibility enables manufacturing personnel to develop and modify welding programs without specialized robotics training.

Offline programming capabilities enable welding program development without interrupting production operations. Engineers can develop and test welding programs using CAD data and simulation tools, then download completed programs to the robot station. This offline development capability maximizes equipment utilization while enabling thorough testing and optimization of welding programs before production implementation.

Vision-guided programming simplifies welding program development for complex parts. The system uses advanced vision systems to automatically generate welding paths based on part geometry, eliminating manual teaching for complex assemblies. This automated programming capability dramatically reduces setup time while ensuring optimal welding sequences for complex geometries.

Collaborative operation modes enable safe interaction between human operators and robotic welding systems. Advanced safety systems monitor the work environment and automatically adjust robot behavior when humans enter the work area. This collaborative capability enables flexible production operations where robots and humans work together effectively.

Industrial Applications and Use Cases

Automotive Manufacturing

The automotive industry represents one of the most demanding applications for robotic welding technology, with requirements for high-volume production, exceptional quality, and the flexibility to accommodate frequent model changes. LD LASER’s 7-Axis Intelligent Welding Robot Station addresses these challenges through advanced automation capabilities specifically designed for automotive manufacturing requirements.

Body-in-white assembly applications benefit significantly from the system’s ability to access complex joint configurations while maintaining optimal welding parameters. Modern vehicle designs incorporate sophisticated structural elements and safety features that require precise welding in challenging positions. The 7-axis configuration enables complete automation of these complex assemblies while ensuring consistent quality across high production volumes.

Chassis and frame welding operations require exceptional precision and strength characteristics that directly impact vehicle safety and performance. The intelligent welding system ensures optimal penetration and fusion in critical structural joints while maintaining the tight tolerances required for proper alignment and fit-up of suspension and drivetrain components. Advanced quality monitoring ensures that every joint meets stringent automotive safety standards.

Battery pack assembly for electric vehicles presents unique challenges including lightweight materials, thermal management requirements, and electrical safety considerations. LD LASER’s welding robot station addresses these challenges through precise control of heat input, specialized welding processes optimized for battery applications, and comprehensive quality monitoring that ensures reliable electrical connections and thermal performance.

Lightweight materials processing capabilities enable automotive manufacturers to achieve weight reduction objectives without compromising structural integrity. The system’s adaptive control technology automatically adjusts welding parameters for aluminum, advanced high-strength steels, and other lightweight materials, ensuring optimal joint properties while maintaining production efficiency.

Heavy Industry and Construction

Heavy industry and construction applications demand welding capabilities that can handle thick materials, large assemblies, and demanding service conditions. LD LASER’s intelligent welding robot station provides the power, precision, and reliability required for these challenging applications while improving productivity and consistency compared to traditional manual welding approaches.

Structural steel fabrication requires precise welding of large assemblies with demanding strength and quality requirements. The robot station’s extended reach and advanced motion capabilities enable complete automation of large structural components while maintaining optimal welding positions throughout the entire assembly. This capability eliminates the manual welding typically required for large structures while ensuring consistent quality and improved productivity.

Pipeline and pressure vessel welding applications demand exceptional quality and reliability due to safety-critical service conditions. The intelligent welding system ensures complete penetration and optimal mechanical properties in critical joints while providing comprehensive documentation and traceability. Advanced quality monitoring capabilities detect potential defects before they compromise service reliability.

Heavy machinery assembly operations benefit from the system’s ability to handle large, complex components while maintaining precise control over welding parameters. Construction equipment, mining machinery, and industrial processing equipment require robust welded assemblies that can withstand extreme operating conditions. The robotic welding system ensures consistent quality while improving productivity compared to manual welding approaches.

Infrastructure component manufacturing for bridges, buildings, and industrial facilities requires welding capabilities that can handle diverse materials and joint configurations. The system’s flexibility and adaptive control enable efficient production of various infrastructure components while maintaining the quality standards required for public safety and long-term reliability.

Aerospace and Defense

Aerospace and defense applications represent the pinnacle of welding quality and precision requirements. Components must meet stringent specifications for strength, reliability, and performance while often incorporating exotic materials and complex geometries. LD LASER’s intelligent welding robot station addresses these demanding requirements through exceptional precision control and comprehensive quality assurance capabilities.

Precision component welding for aerospace applications requires positioning accuracy and repeatability that exceeds typical industrial standards. The robot station’s advanced motion control and precision feedback systems ensure consistent welding conditions for critical components where variations could compromise performance or safety. This precision proves essential for turbine components, structural elements, and flight control systems.

Aluminum and titanium processing capabilities enable automated welding of lightweight aerospace materials that traditionally require specialized manual welding techniques. The system’s adaptive control technology automatically optimizes welding parameters for these challenging materials while maintaining the stringent quality requirements typical of aerospace applications. This automation capability improves consistency while reducing the dependency on highly skilled manual welders.

Complex assembly operations for aircraft and defense systems often involve intricate geometries and multiple materials that challenge conventional automation approaches. The 7-axis configuration provides the flexibility necessary to access all required joints while maintaining optimal welding conditions. This capability enables automation of assemblies previously requiring extensive manual welding operations.

High-reliability applications demand welding quality that ensures consistent performance throughout extended service lives under demanding conditions. The intelligent welding system’s comprehensive quality monitoring and documentation capabilities provide the traceability and reliability assurance required for aerospace and defense applications where failure is not an option.

Shipbuilding and Marine

Shipbuilding and marine applications present unique challenges including large-scale assemblies, diverse materials, and demanding service environments. LD LASER’s welding robot station addresses these challenges through capabilities specifically designed for marine manufacturing requirements while improving productivity and quality compared to traditional shipbuilding welding methods.

Hull section assembly operations require welding capabilities that can handle large plates and complex curvatures while maintaining structural integrity and watertight sealing. The robot station’s extended reach and advanced motion capabilities enable automated welding of large hull sections while ensuring consistent penetration and quality throughout the entire assembly.

Complex joint configurations common in shipbuilding applications include multiple angles, varying thicknesses, and specialized sealing requirements. The intelligent welding system adapts automatically to these varying conditions while maintaining optimal welding parameters for each joint type. This adaptability enables automation of complex assemblies previously requiring extensive manual welding operations.

Large structure welding for commercial vessels, naval ships, and offshore platforms demands capabilities that can handle massive assemblies while maintaining precision and quality. The system’s combination of reach, precision, and adaptive control enables effective automation of these challenging applications while improving productivity and consistency compared to manual welding approaches.

Maritime equipment fabrication including propulsion systems, deck machinery, and specialized marine equipment requires welding capabilities that ensure reliable performance in harsh marine environments. The intelligent welding system provides the quality control and documentation necessary for marine applications while enabling efficient production of specialized equipment components.

Performance Advantages

Productivity Enhancement

The productivity advantages delivered by LD LASER’s 7-Axis Intelligent Welding Robot Station extend far beyond simple speed improvements to encompass fundamental changes in manufacturing efficiency and capability. Continuous operation capabilities enable 24/7 production without the fatigue limitations that constrain human welders, dramatically increasing effective production capacity without requiring additional floor space or facility expansion.

Reduced cycle times result from optimized welding sequences, elimination of setup and positioning delays, and consistent high-speed operation. The intelligent path planning algorithms calculate optimal welding sequences that minimize non-productive time while ensuring complete access to all required joints. This optimization proves particularly valuable in high-volume production where small cycle time improvements translate into significant productivity gains.

Minimal setup and changeover requirements enable efficient production of diverse part mixes without extensive downtime between jobs. The system’s offline programming capabilities and automated tool changing enable rapid transitions between different welding operations, supporting flexible manufacturing approaches that respond effectively to changing customer demands.

The 24/7 production potential provides manufacturers with significant capacity advantages while optimizing labor utilization. Unmanned operation during off-shifts maximizes equipment utilization while enabling manufacturing personnel to focus on higher-value activities during normal working hours. This capability proves particularly valuable in markets where delivery performance provides competitive advantages.

Quality Improvements

Consistent weld quality represents one of the most significant advantages of intelligent robotic welding systems. Unlike manual welding operations that can vary based on operator skill, fatigue, and environmental conditions, the robotic system maintains optimal welding parameters consistently throughout extended production runs. This consistency eliminates the quality variations that can compromise product performance or require costly rework operations.

Reduced human error eliminates the variability inherent in manual welding operations while ensuring that welding procedures are followed precisely for every joint. The system’s automated parameter control and quality monitoring eliminate the possibility of operator error while ensuring that every weld meets specified requirements. This reliability proves particularly valuable in safety-critical applications where weld quality directly impacts product performance.

Repeatable results enable manufacturers to achieve consistent product quality while reducing inspection and testing requirements. The system’s precision control and quality monitoring capabilities ensure that welding results remain consistent across production runs, enabling statistical quality control approaches that reduce inspection costs while maintaining quality assurance.

Enhanced precision control enables welding operations that exceed the capabilities of manual welding approaches. The system’s ability to maintain precise heat input, travel speed, and positioning throughout complex welding operations ensures optimal mechanical properties while minimizing distortion and residual stresses that can compromise product performance.

Cost Optimization

Labor cost reduction represents a fundamental advantage of robotic welding automation, particularly in markets where skilled welders are scarce and expensive. The system enables manufacturers to reduce dependency on specialized welding personnel while redirecting human resources to higher-value activities that cannot be automated effectively. This labor optimization improves cost competitiveness while addressing skilled labor shortage challenges.

Material waste minimization results from precise control over welding parameters and elimination of rework requirements. The system’s adaptive control and quality monitoring capabilities ensure optimal material utilization while reducing the scrap and rework costs associated with welding defects. This efficiency improvement proves particularly valuable when processing expensive materials or operating under tight margin conditions.

Energy efficiency improvements result from optimized welding parameters and elimination of idle time associated with manual operations. The intelligent control system ensures that energy consumption remains optimal throughout welding operations while advanced scheduling algorithms minimize equipment idle time. These efficiency improvements reduce operating costs while supporting sustainability objectives.

Maintenance cost optimization results from predictive maintenance capabilities and reduced wear from consistent operating conditions. The system’s condition monitoring and predictive analytics enable proactive maintenance scheduling that minimizes unexpected downtime while optimizing maintenance intervals. This approach reduces maintenance costs while ensuring maximum equipment availability.

Safety Benefits

Hazardous environment operation capabilities enable welding operations in conditions that would be dangerous or impossible for human operators. The robotic system can operate effectively in confined spaces, elevated positions, or environments with toxic fumes or extreme temperatures. This capability expands manufacturing possibilities while ensuring worker safety in challenging applications.

Reduced operator exposure to welding hazards including ultraviolet radiation, toxic fumes, and high temperatures improves workplace safety while reducing health-related costs and liability. Operators can monitor and control welding operations from safe distances while focusing on higher-level tasks that require human judgment and expertise.

Improved workplace safety results from elimination of manual welding operations in dangerous positions or environments. The system’s reach and flexibility enable welding operations that would require extensive scaffolding, confined space entry, or other high-risk activities for manual welding. This safety improvement reduces accident risks while improving overall workplace safety performance.

Compliance with safety standards becomes easier to achieve and maintain through comprehensive documentation and consistent operating procedures. The system’s automated safety monitoring and documentation capabilities ensure that safety requirements are met consistently while providing the records necessary for regulatory compliance and safety audits.

Technical Specifications and Features

Mechanical Specifications

The mechanical foundation of LD LASER’s 7-Axis Intelligent Welding Robot Station reflects years of engineering refinement focused on delivering exceptional performance, reliability, and precision. The payload capacity reaches 20kg with extended reach capabilities exceeding 3.5 meters, providing the combination of strength and flexibility necessary for demanding industrial welding applications.

Positioning accuracy maintains ±0.05mm repeatability across the full working envelope, ensuring consistent weld placement and dimensional accuracy for precision applications. This accuracy specification exceeds typical industrial robot performance while providing the precision necessary for aerospace, automotive, and other demanding applications where tight tolerances are essential.

Speed and acceleration capabilities optimize productivity while maintaining precision and quality. Maximum joint speeds reach 180°/second with acceleration rates that enable rapid positioning between welding operations. The advanced motion control system ensures smooth acceleration and deceleration that minimizes vibration while optimizing cycle times for high-volume production applications.

Environmental operating conditions accommodate industrial manufacturing environments with temperature ranges from 0°C to 45°C and humidity tolerance up to 95% relative humidity. The robust mechanical design incorporates sealed bearing systems and protective coatings that ensure reliable operation in demanding industrial environments including foundries, shipyards, and heavy manufacturing facilities.

The structural design incorporates high-strength steel construction with precision machined components that ensure long-term accuracy and reliability. Advanced vibration damping systems minimize the effects of external disturbances while maintaining welding precision even in facilities with significant floor vibrations from heavy machinery or material handling equipment.

Welding Capabilities

Process compatibility encompasses the full range of industrial welding processes including MIG (GMAW), TIG (GTAW), and plasma welding applications. Advanced power source integration enables automatic process selection and parameter optimization based on application requirements, material types, and quality specifications. This versatility enables the system to address diverse welding requirements within a single installation.

Material thickness ranges span from 0.8mm sheet metal applications to heavy plate welding exceeding 50mm thickness. The intelligent control system automatically adjusts welding parameters based on material thickness while maintaining optimal penetration and quality characteristics. This broad capability range eliminates the need for multiple specialized welding systems while addressing diverse production requirements.

Joint configuration capabilities include butt joints, fillet welds, lap joints, and complex three-dimensional seam configurations. The 7-axis motion capability enables optimal torch positioning for any joint geometry while maintaining proper welding angles and standoff distances. This flexibility ensures that complex assemblies can be welded completely without repositioning or multiple setups.

Welding speed specifications reach up to 2.5 meters per minute for typical fillet weld applications with speeds optimized automatically based on material type, thickness, and quality requirements. The intelligent speed control ensures optimal productivity while maintaining consistent penetration and mechanical properties throughout the welding operation.

Wire feed capabilities accommodate wire diameters from 0.8mm to 1.6mm with automatic adjustment based on welding parameters and material requirements. Advanced wire feeding systems ensure consistent wire delivery while minimizing feeding issues that can compromise weld quality or interrupt production operations.

Control and Software Features

Programming languages and interfaces provide multiple options for welding program development including teach pendant programming, offline programming, and direct CAD integration. The intuitive graphical interface simplifies complex programming tasks while providing access to advanced features for specialized applications. Multiple programming approaches ensure that the system can be integrated effectively into diverse manufacturing environments with varying technical capabilities.

Safety monitoring systems incorporate comprehensive collision detection, workspace monitoring, and emergency stop capabilities that ensure safe operation in industrial environments. Advanced sensor systems continuously monitor the work area while predictive collision avoidance prevents accidents before they occur. These safety features enable safe operation in collaborative environments where humans and robots work in proximity.

Communication protocols include standard industrial networking options including Ethernet/IP, Profinet, and DeviceNet interfaces that enable seamless integration with existing manufacturing systems. Advanced communication capabilities support real-time data exchange with MES, ERP, and quality management systems while enabling remote monitoring and control capabilities.

Upgrade and expansion capabilities ensure long-term value through modular software architecture that accommodates future enhancements and additional functionality. The system’s open architecture enables integration of new sensors, welding processes, and automation features as requirements evolve. This expandability protects customer investments while ensuring continued competitiveness as technology advances.

Implementation and Integration

Installation and Commissioning

Site preparation requirements for LD LASER’s 7-Axis Intelligent Welding Robot Station focus on creating optimal conditions for precision welding operations while accommodating the system’s advanced capabilities. Foundation specifications ensure adequate support for the robot system while minimizing vibrations that could affect welding precision. Power requirements include standard industrial electrical service with appropriate grounding for sensitive electronic systems.

System integration procedures encompass mechanical installation, electrical connections, and software configuration tailored to specific application requirements. LD LASER’s experienced installation teams work closely with customer personnel to ensure optimal system placement and integration with existing production lines and material handling systems. The comprehensive integration approach minimizes installation time while ensuring optimal performance from startup.

Testing and validation protocols verify system performance against specifications while demonstrating capabilities for specific customer applications. Comprehensive testing includes accuracy verification, speed validation, and quality assessment using customer materials and specifications. This thorough validation ensures that performance expectations are met before production operations begin.

Performance optimization activities fine-tune system parameters for optimal productivity and quality in specific applications. LD LASER’s applications engineers work with customer personnel to optimize welding parameters, motion sequences, and quality monitoring settings for maximum performance. This optimization ensures that customers achieve maximum value from their technology investment.

Documentation and training materials provide comprehensive guidance for operation, maintenance, and troubleshooting. Complete technical documentation includes operation manuals, maintenance procedures, and troubleshooting guides that enable customer personnel to operate and maintain the system effectively. Comprehensive documentation ensures long-term success while minimizing dependency on external support.

Training and Support

Operator training programs provide comprehensive instruction in system operation, programming, and basic maintenance procedures. Structured training curricula accommodate varying skill levels while ensuring that operators can utilize the system’s full capabilities effectively. Hands-on training with customer applications ensures that operators gain practical experience with their specific welding requirements.

Maintenance training curricula cover preventive maintenance procedures, troubleshooting techniques, and component replacement procedures that enable customer personnel to maintain optimal system performance. Advanced training options include specialized topics such as advanced programming, process optimization, and integration with other manufacturing systems.

Technical support services provide ongoing assistance for operational questions, troubleshooting support, and performance optimization. LD LASER’s global support network ensures that technical assistance is available when needed while remote diagnostic capabilities enable immediate support for many common issues. Comprehensive support ensures maximum equipment availability and optimal performance.

Continuous improvement programs provide ongoing opportunities for performance enhancement and capability expansion. Regular performance reviews identify optimization opportunities while technology updates ensure access to the latest advances in welding automation. These programs ensure that customer investments continue to provide competitive advantages throughout the equipment lifecycle.

ROI and Business Case

Investment analysis framework provides structured approaches for evaluating the financial benefits of robotic welding automation. Comprehensive cost-benefit analysis includes labor savings, productivity improvements, quality enhancements, and reduced waste to demonstrate financial returns. Detailed analysis tools enable customers to develop compelling business cases for automation investment.

Payback period calculations typically demonstrate returns within 18-24 months for most applications, with shorter payback periods for high-volume operations or applications with significant manual welding labor costs. The rapid payback reflects substantial productivity and quality improvements that deliver immediate competitive advantages while providing long-term cost reductions.

Productivity improvement metrics demonstrate significant increases in throughput, quality, and efficiency compared to manual welding operations. Typical improvements include 2-3x productivity increases, 50-75% reduction in rework requirements, and 90%+ improvement in quality consistency. These improvements translate directly into competitive advantages and improved profitability.

Long-term value proposition extends beyond immediate productivity improvements to include strategic advantages such as improved capability, enhanced reputation, and expanded market opportunities. The technology investment positions customers for future growth while providing the flexibility to adapt to changing market requirements and customer expectations.

Future Developments and Roadmap

Technology Evolution

Advanced AI integration represents the next frontier in intelligent welding automation, with machine learning algorithms that continuously optimize welding performance based on real-world results. Future developments will incorporate predictive quality control, autonomous parameter optimization, and self-learning capabilities that enable the system to improve performance automatically over time.

Enhanced sensor capabilities will expand quality monitoring and adaptive control functionalities while enabling new applications and improved performance. Advanced vision systems, thermal monitoring, and acoustic sensors will provide comprehensive process monitoring that ensures optimal quality while enabling real-time optimization of welding parameters.

Improved human-robot collaboration will enable more flexible manufacturing approaches where humans and robots work together effectively on complex assemblies. Advanced safety systems and intuitive interfaces will simplify collaboration while ensuring safety in shared work environments. These developments will expand automation possibilities while maintaining human oversight for complex decisions.

Next-generation control systems will incorporate cloud computing, edge processing, and advanced analytics that enable real-time optimization and predictive maintenance. These advanced control capabilities will improve performance while reducing operating costs and maintenance requirements. Future control systems will enable autonomous operation with minimal human intervention while maintaining optimal performance.

Market Expansion

Emerging application areas include additive manufacturing integration, hybrid processing capabilities, and specialized materials processing that expand the range of applications suitable for robotic welding. Future developments will address new markets and applications while maintaining the performance advantages that define LD LASER’s technology leadership.

Geographic market development focuses on expanding global availability while providing local support capabilities that ensure customer success. Regional manufacturing and support facilities will provide localized service while maintaining global technology standards and capabilities.

Technology partnerships with leading suppliers and research institutions accelerate development while ensuring access to cutting-edge technologies and capabilities. Strategic partnerships enable rapid development and deployment of new capabilities while maintaining technology leadership in competitive markets.

Customer success stories demonstrate real-world performance and provide valuable feedback for continued development. Successful implementations provide reference installations that support market expansion while validating technology capabilities in diverse applications and industries.

Sustainability and Environmental Impact

Energy efficiency improvements focus on reducing power consumption while maintaining performance through advanced power management and optimized control systems. Future developments will incorporate renewable energy integration and energy recovery systems that minimize environmental impact while reducing operating costs.

Waste reduction capabilities minimize material waste through precise control and optimized processes while enabling recycling and reuse of welding consumables. Advanced process monitoring ensures optimal material utilization while reducing environmental impact and operating costs.

Environmental compliance support ensures that welding operations meet increasingly stringent environmental regulations while minimizing impact on air and water quality. Advanced filtration and emission control systems will enable compliance with environmental requirements while maintaining productive operations.

Green manufacturing support includes capabilities that enable sustainable production practices and support customer sustainability objectives. Future developments will incorporate lifecycle assessment tools and environmental impact monitoring that enable customers to achieve their sustainability goals while maintaining competitive performance.

Conclusion: Transforming Manufacturing Through Intelligent Automation

LD LASER’s 7-Axis Intelligent Welding Robot Station represents more than a technological advancement—it embodies a fundamental transformation in how manufacturers approach welding automation and production optimization. This revolutionary system addresses the most pressing challenges facing modern manufacturing while providing the foundation for continued innovation and competitive advantage.

The comprehensive capabilities spanning mechanical flexibility, intelligent control, and advanced integration position this technology as the definitive solution for manufacturers seeking to enhance productivity, improve quality, and reduce costs. The system’s ability to adapt to diverse applications while maintaining exceptional performance ensures that customers achieve maximum value from their automation investments.

As manufacturing continues to evolve toward smarter, more efficient, and increasingly automated operations, LD LASER’s intelligent welding robot station provides the technological foundation necessary for success. The combination of proven performance, advanced capabilities, and comprehensive support ensures that customers can achieve their production objectives while positioning themselves for future growth and success.

The investment in intelligent welding automation represents more than equipment acquisition—it represents a commitment to manufacturing excellence and competitive advantage. Organizations that embrace this technology today position themselves as leaders in their respective markets while building the foundation for sustained success in an increasingly competitive global marketplace.

Ready to revolutionize your welding operations? Contact LD LASER today to discover how our 7-Axis Intelligent Welding Robot Station can transform your manufacturing capabilities and provide the competitive advantages necessary for success in today’s demanding industrial environment. Experience the future of automated manufacturing and unlock your facility’s full production potential.