Global Manufacturing Leaders Invited to Witness the Future of Metal Processing

A Historic Moment for European Manufacturing

LD LASER, China’s pioneering force in high-power laser cutting technology, proudly announces the European debut of its groundbreaking LD-6025E-60kW Fiber Laser Cutting Machine on September 30, 2025, in Trenčín, Nové Mesto nad Váhom, Slovakia. This landmark event marks the first European stop in LD LASER’s global market expansion, bringing cutting-edge 60kW laser technology directly to European manufacturers who demand nothing but the absolute best in metal processing capabilities.

As the world’s leading innovator in ultra-high-power laser systems, LD LASER has consistently pushed the boundaries of what’s possible in metal processing. Our revolutionary 60kW system represents the pinnacle of laser cutting technology, specifically engineered for the most demanding heavy industrial applications including shipbuilding, construction machinery, mining equipment, and rail transit manufacturing where precision and power must work in perfect harmony.

Revolutionary 60kW Technology: Redefining Industrial Capabilities

Unmatched Power and Precision

The LD-6025E-60kW delivers unprecedented cutting capabilities with its massive 60,000-watt fiber laser system. This powerhouse machine features:

- Processing Area: 6000×2500mm for large-format industrial components

- Exceptional Precision: ±0.03mm/m positioning accuracy with ±0.02mm/m repeatability

- High-Speed Performance: 150m/min maximum operating speed with 1.5G acceleration

- Versatile Z-Axis: 400mm travel range for complex geometries

Advanced Engineering Excellence

Built on LD LASER’s proprietary E-Series platform, the LD-6025E features:

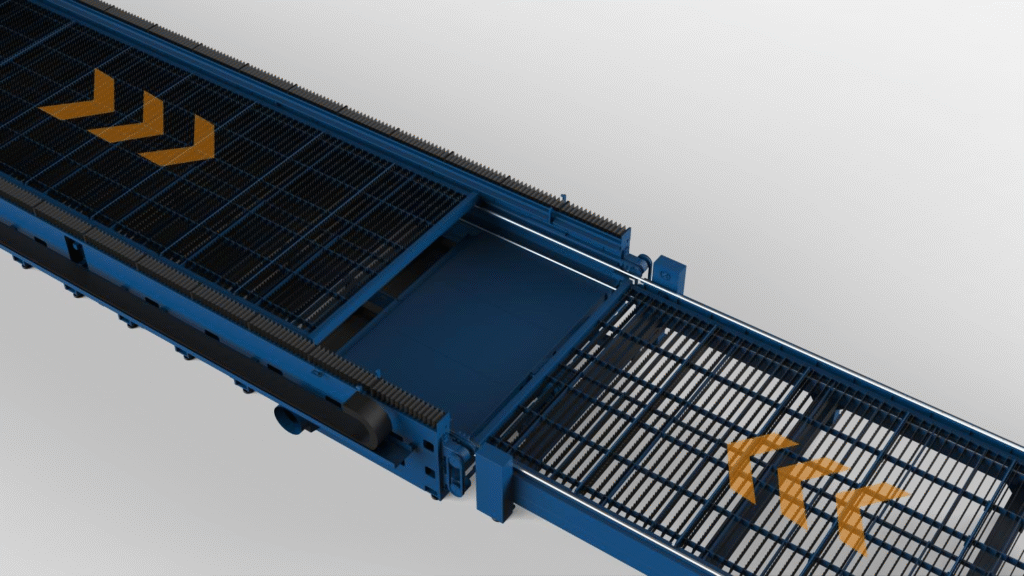

Dual-Table Exchange Design: Revolutionary configuration enabling simultaneous cutting and loading/unloading, dramatically reducing idle time and maximizing productivity. The fully separated work zones ensure operator safety while maintaining continuous operation.

Enclosed Safety Architecture: Upgraded thickened enclosure with comprehensive safety systems, containing cutting fumes and preventing spark-related hazards. Front-positioned material handling facilitates easy maintenance access.

Intelligent Monitoring Systems: Interconnected dual-screen design allows real-time cutting condition monitoring while operating the machine, ensuring optimal performance and quality control.

High-Strength Steel Construction: Integrated steel beam design with tempered stress relief ensures long-term precision stability without deformation, even under continuous heavy-duty operation.

Cutting-Edge Technology Features

Mixed Gas Cutting Innovation

For applications demanding the full 60kW power capability, LD LASER has developed and perfected advanced mixed gas cutting technology that combines nitrogen and oxygen in precisely controlled ratios. This innovative approach delivers superior cut quality through effective slag removal and dramatically reduced burr formation, resulting in finished surfaces that often require no secondary processing. The enhanced energy transfer efficiency of mixed gas cutting enables faster cutting speeds while simultaneously reducing operational costs compared to traditional single-gas systems.

Beyond the immediate performance benefits, mixed gas cutting provides significant environmental advantages by reducing hazardous emissions and improving overall workplace safety. The system’s enhanced penetration power enables the cutting of thicker materials that would be impossible or impractical with lower-power systems, opening new possibilities for manufacturers who work with heavy-gauge materials.

Advanced CNC Control System

The heart of the LD-6025E lies in its sophisticated control platform that brings together decades of laser cutting expertise with modern computing power. The system’s intuitive interface design makes complex operations straightforward while providing the depth of control that experienced operators demand. Real-time cutting parameter adjustment capabilities ensure optimal quality throughout the cutting process, while automatic cutting head calibration with enhanced Z-axis response maintains perfect focus positioning even during the most demanding operations.

Advanced cutting functions including jump cutting, laser power control, and multi-axis synchronization work seamlessly together to optimize cutting paths and minimize processing time. The system’s Ethernet connectivity enables seamless program transfer from design workstations, while comprehensive status monitoring and position visualization keep operators fully informed of system performance at all times.

Professional Water Cooling System

The LD-6025E’s dual-channel temperature control system represents a significant advancement in laser cooling technology, enabling independent temperature regulation for both the laser source and cutting head. This sophisticated approach ensures optimal performance under all operating conditions while providing comprehensive monitoring including water pressure alarms, temperature alerts, and fault detection systems that protect the substantial investment in laser technology.

LD LASER: Global Industry Leadership

Manufacturing Excellence and Innovation Pioneer

Since our founding in 2012 and the beginning of laser cutting machine production in 2014, LD LASER has grown from an ambitious startup to the undisputed global leader in high-power laser cutting technology. Our journey to first-tier status among high-power laser cutting manufacturers began in earnest in 2017, and today we proudly hold the market-leading position in high-power laser cutting machine market share worldwide.

Our impressive 60,000-square-meter manufacturing facility produces over 3,000 units annually, with approximately 1,500 laser cutting machines exported to markets across Europe, the Americas, Southeast Asia, the Middle East, and Africa. This global reach reflects not just our manufacturing capability, but our commitment to supporting customers wherever advanced manufacturing takes place.

What truly sets LD LASER apart is our position as the world’s first company to successfully launch high-power laser systems of 40kW, 50kW, 60kW, 80kW, 120kW, and 200kW. This consecutive four-year leadership in ultra-high-power laser innovation demonstrates our unwavering commitment to pushing the boundaries of what’s possible in laser cutting technology.

Quality Assurance and Technical Expertise

Our commitment to excellence is validated through comprehensive certifications including CE, ROHS, and ISO9001 quality management systems, ensuring that every machine meets the highest international standards. Our complete in-house manufacturing process encompasses everything from laser cutting and mechanical design to welding, gantry milling, and heat treatment, giving us unprecedented control over quality at every stage of production.

The technical expertise of our team represents one of our greatest assets, with the industry’s most experienced process and manufacturing engineers continuously refining our designs and manufacturing methods. Our rigorous 12-step production process ensures that every machine leaving our facility meets the exceptional standards that have made LD LASER the preferred choice of manufacturers worldwide.

Why Attend This Exclusive European Premiere?

Experience the Future of Manufacturing

This exclusive European premiere offers an unparalleled opportunity to witness 60kW laser cutting technology in action, providing firsthand experience of capabilities that will reshape your understanding of what’s possible in metal processing. Our expert engineers will be on hand to provide detailed technical consultations, helping you understand exactly how this revolutionary technology can transform your specific manufacturing operations.

The event includes comprehensive material testing opportunities, allowing you to see your own materials processed with 60kW technology and compare the results with your current equipment capabilities. This practical demonstration approach ensures that you leave the event with concrete understanding of the performance improvements and new possibilities that LD LASER technology brings to your operations.

Business Development and Strategic Opportunities

Beyond the technical demonstrations, this event represents a unique business development opportunity to explore distribution and collaboration possibilities with LD LASER. As we expand our European presence, we’re actively seeking strategic partners who share our commitment to manufacturing excellence and customer success.

The event provides valuable market insights into European laser cutting trends and applications, helping you understand how advanced technology can provide competitive advantages in your specific market segments. Early access to this game-changing technology positions your company at the forefront of manufacturing innovation, opening new market opportunities and enabling you to offer superior services to your customers.

Networking and Industry Connections

The carefully curated attendee list ensures meaningful networking opportunities with European manufacturing executives, technology partners, and industry leaders. These connections often prove as valuable as the technology itself, creating ongoing relationships that support business development and technological advancement for years to come.

Comprehensive Applications Across Industries

The LD-6025E-60kW excels in demanding applications including:

- 조선: Heavy plate cutting for marine construction

- 건설 기계: Large structural components manufacturing

- Mining Equipment: Heavy-duty machinery part production

- Rail Transit: Precision components for transportation systems

- Energy Sector: Wind power and renewable energy component fabrication

- 항공우주: High-precision cutting for aviation applications

Investment in Your Manufacturing Future

Transforming Operational Excellence

The LD-6025E-60kW represents more than just an equipment purchase; it’s an investment in transforming your manufacturing capabilities and operational excellence. The system’s optimized energy efficiency and advanced gas consumption management significantly reduce operating costs while delivering faster cutting speeds and superior quality that enhances your competitive position in the marketplace.

The enhanced capability to process thicker materials with exceptional precision opens new market opportunities and enables you to take on projects that were previously impossible or unprofitable. Advanced safety systems protect both operators and facility infrastructure while comprehensive global support ensures that your investment continues to deliver value for years to come.

Long-Term Strategic Value

Choosing LD LASER technology means positioning your company at the forefront of manufacturing innovation, ensuring that you maintain technology leadership as markets evolve and customer demands become increasingly sophisticated. The scalable nature of our solutions enables business growth and expansion while our comprehensive global support network provides the security of knowing that expert assistance is always available when needed.

Comprehensive After-Sales Support

LD LASER’s commitment to customer success extends far beyond the initial equipment delivery through our comprehensive European support infrastructure. Professional installation and operator training ensure that your team can maximize the capabilities of your new equipment from day one, while our technical support team provides two-hour response times for any technical issues that may arise.

Our comprehensive spare parts inventory and advanced remote diagnostic capabilities minimize downtime and ensure that your production schedules remain on track. The full one-year comprehensive warranty provides additional peace of mind, backed by LD LASER’s global reputation for reliability and customer service excellence.

Join Us in Slovakia – Reserve Your Place

This exclusive European premiere offers limited attendance to ensure personalized attention and meaningful interactions. As a manufacturing leader, this is your opportunity to:

✓ Experience revolutionary 60kW laser cutting technology

✓ Evaluate how this technology can transform your operations

✓ Network with European industry leaders and LD LASER experts

✓ Explore partnership and collaboration opportunities

✓ Secure early access to game-changing manufacturing capabilities

Event Details:

- Date: September 30, 2025

- Location: Trenčín, Nové Mesto nad Váhom, Slovakia

- Duration: Full-day technical demonstration and consultation

- Registration: Limited capacity – advance registration required

Contact Information & Registration

Join the Manufacturing Revolution

Don’t miss this historic opportunity to witness the future of laser cutting technology on European soil. Contact us today to secure your place at this exclusive event.

LD LASER Global Headquarters

- Website: www.ldlaser.com

- Service Hotline: 400-615-5758

- Address: No. 4685 Kaiyuan Street, Shanghe Economic Development Zone, Jinan City, Shandong Province

“We cordially invite customers and partners from around the world to experience this revolutionary technology firsthand. Together, we’ll shape the future of manufacturing.”

LD LASER – Leading in High Power, Choose LD LASER

Seeking Global Distributors