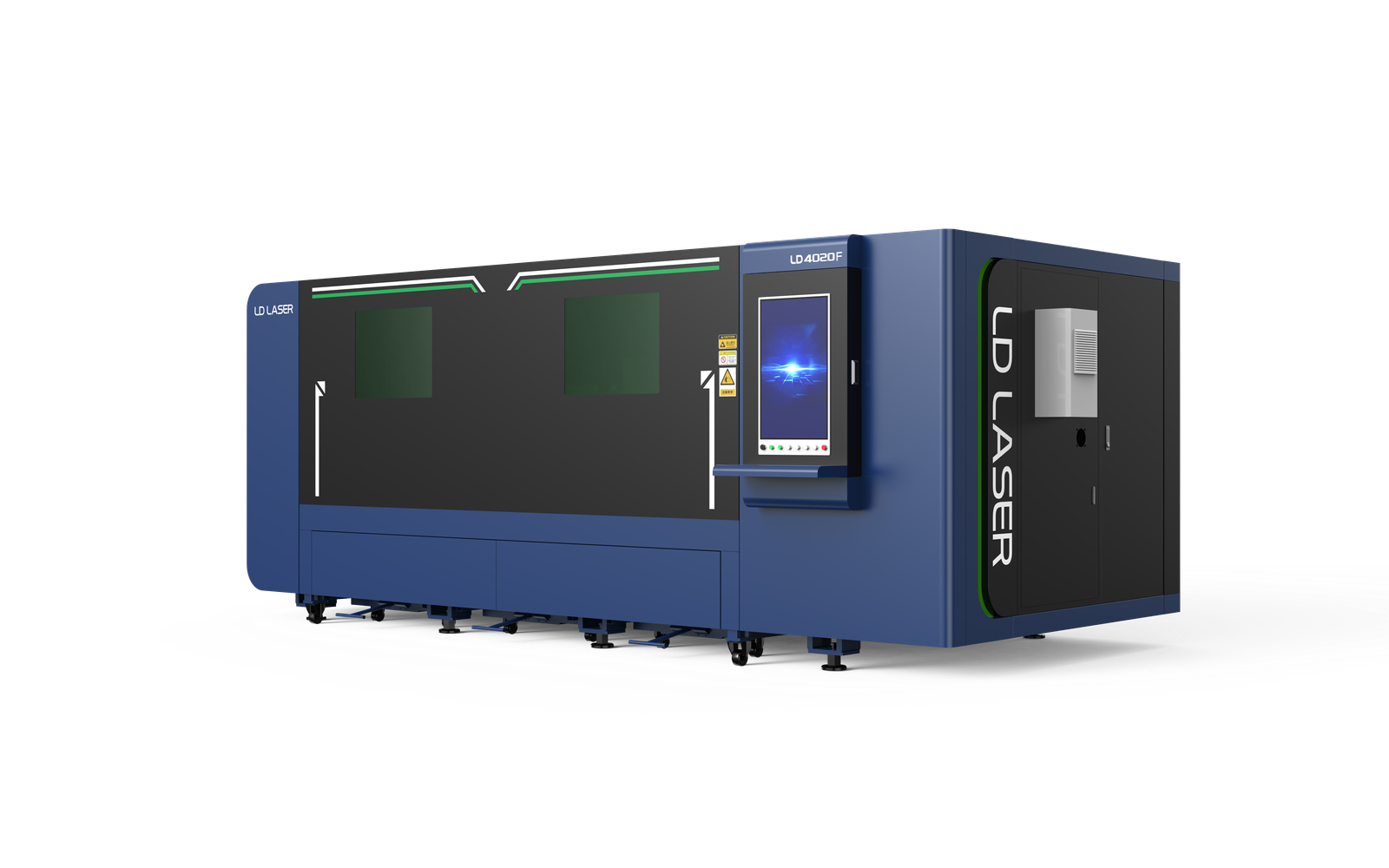

Single Table Panel Fiber Laser Cutting Machine

The integrated welding process ensures strong and uniform welds, enhancing impact and torsion resistance; high-temperature annealing further eliminates welding and processing stresses, preventing deformation over long-term use, reducing cutting deviations and workpiece scrap rates, and minimizing downtime for debugging.

Rectangular steel is welded to form a classic gantry structure

Annealing to relieve stress and process the shape

Greatly improve the bearing capacity of the beam

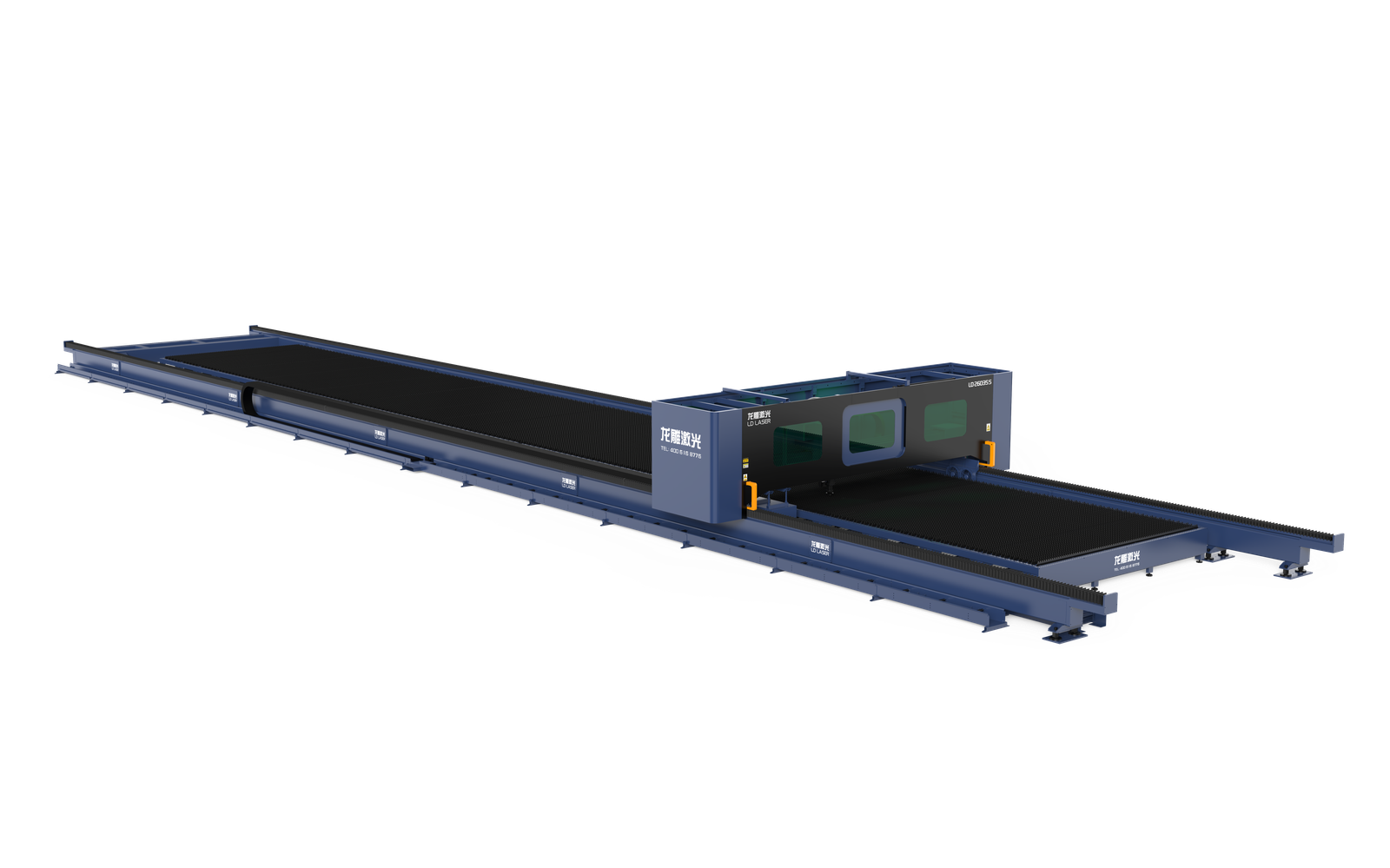

The single-platform open structure supports flexible loading and unloading from three directions: left, right, and front. It adapts to different workpiece sizes and production scenarios, making it suitable for batch processing. This reduces operational difficulty and improves operational safety and convenience.

This component converts the sliding friction between the workpiece and the worktable into rolling friction, allowing a single person to push heavy workpieces and significantly reducing resistance. It better protects both the workpiece and the machine, preventing damage caused by direct friction between the workpiece and the worktable, and allows for precise position adjustment, shortening positioning time in conjunction with loading and unloading processes.

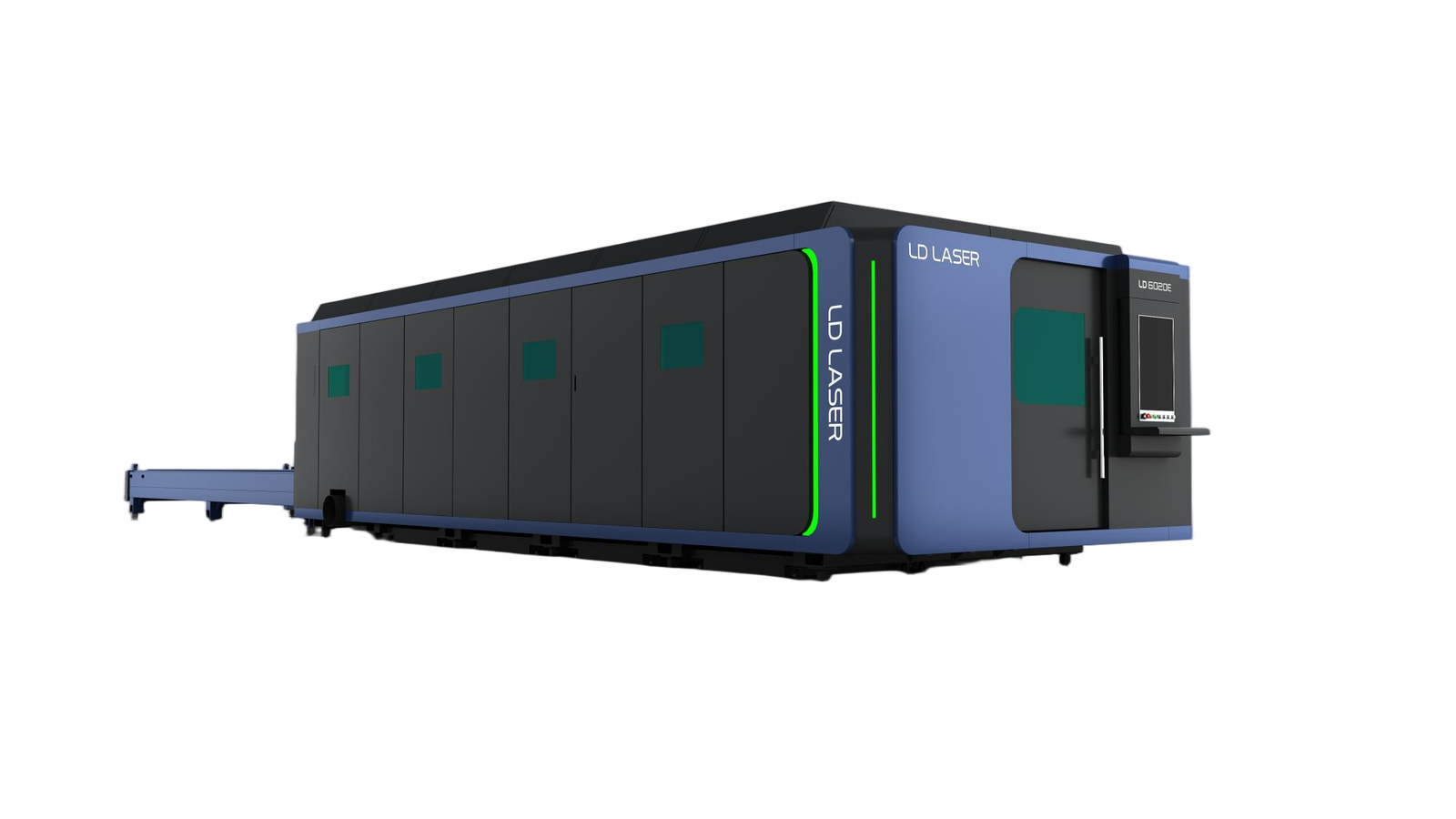

Integrates control and display functions, with operations and displays centrally located for convenient parameter adjustment, program startup, and other operations, improving efficiency, saving space, providing real-time feedback and visual operation, and reducing operational difficulty.

The integrated bed design with built-in electrical cabinet makes transportation more convenient, ensures safer and more stable wiring, reduces the customer’s floor space, and greatly improves the utilization rate of the customer’s site.

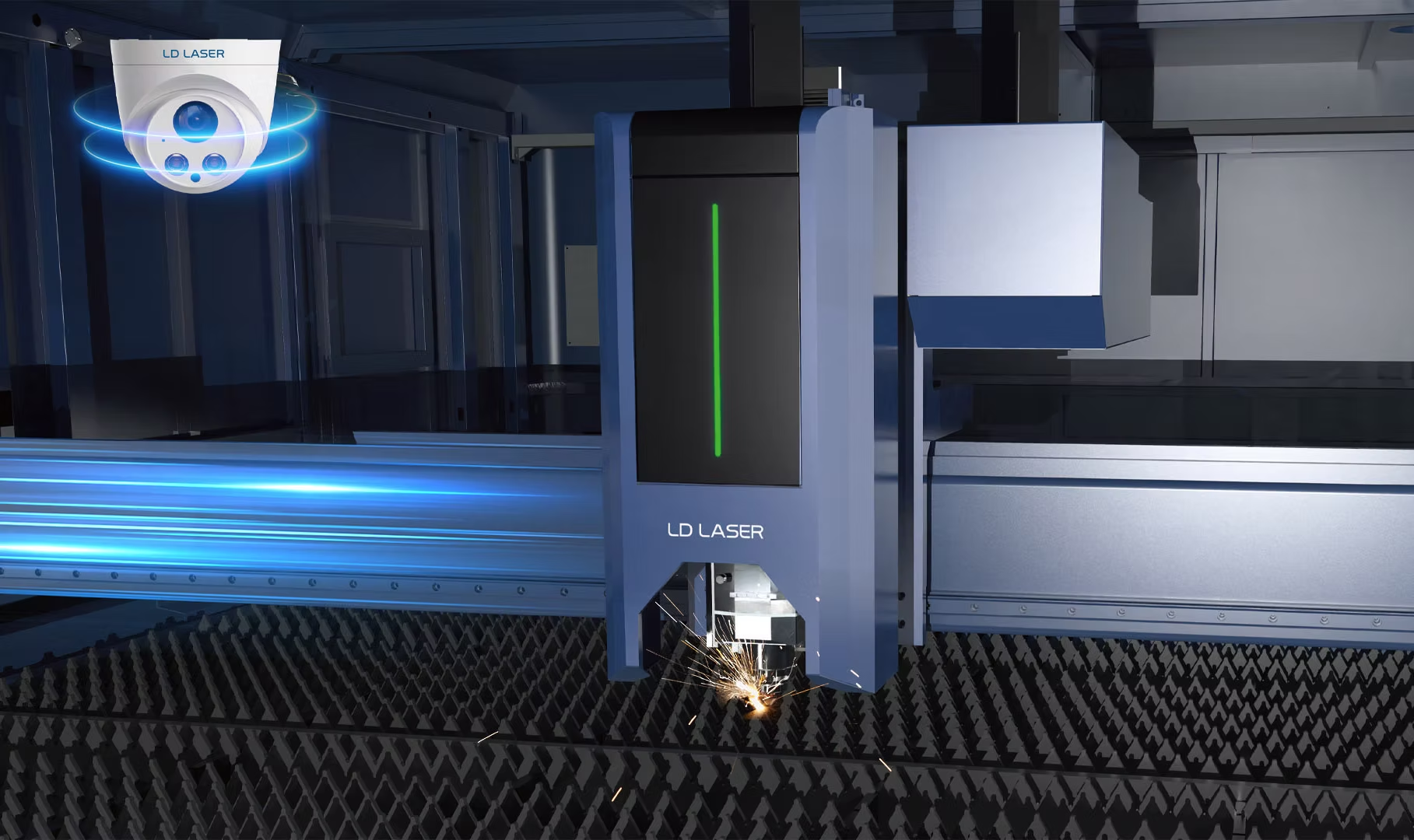

The cutting quality can be judged through the equipment sensors, and the parameters can be adjusted in real time to improve the cutting efficiency and stability.

Based on the actual cutting conditions of the equipment, we can achieve smarter, safer, more convenient and more efficient processing

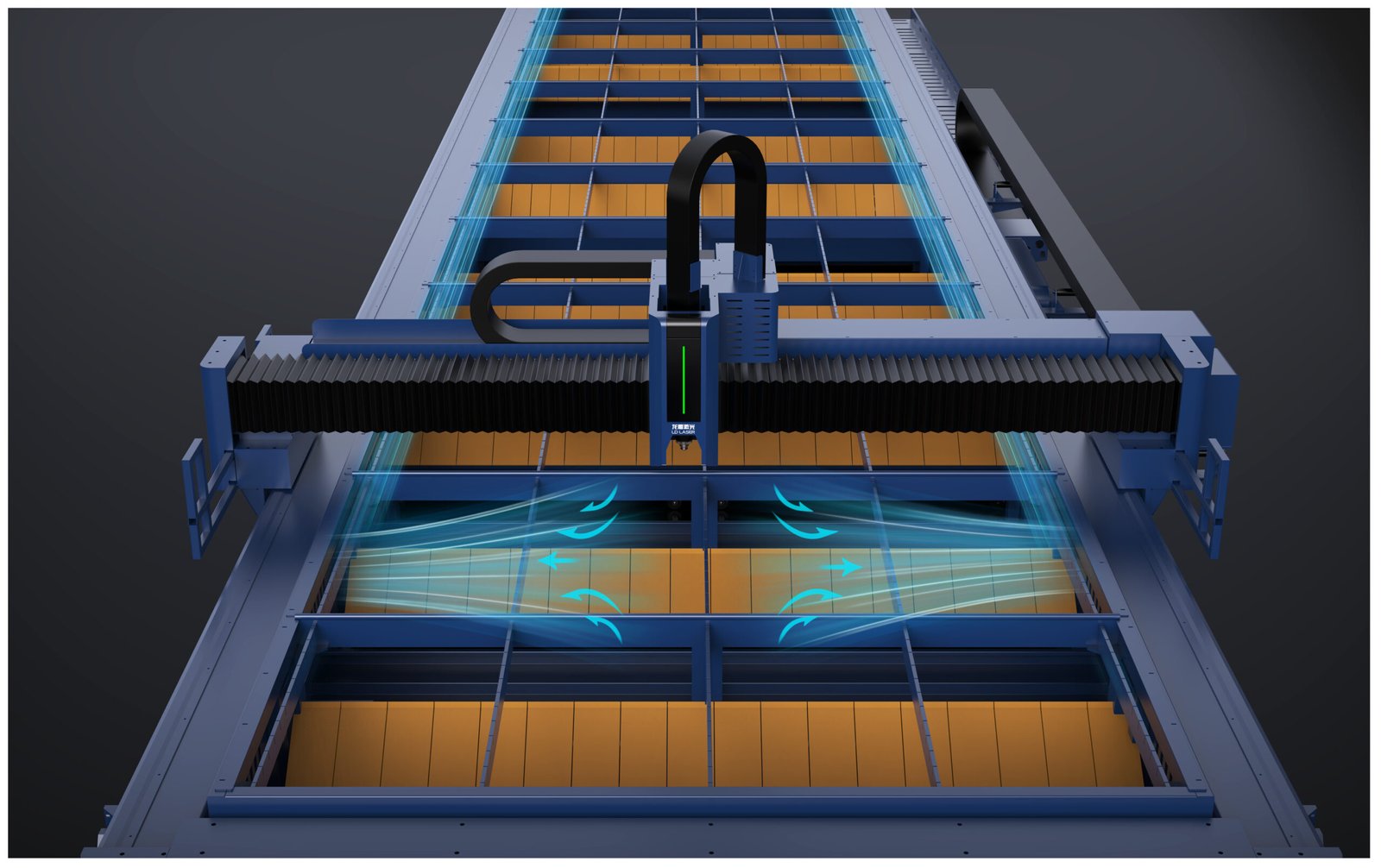

The ultra-large diameter air duct design is adopted, with independent control and partitioned dust removal to improve the smoke exhaust and heat removal effects

Equipped with ultra-high-definition large-size industrial control screen, equipped with intelligent control system, rich functions, intelligent adjustment, safe production

Through intelligent system monitoring, real-time adjustment of air pressure detection to ensure stable cutting

The equipment’s all-round monitoring system records the entire process of workpiece cutting while ensuring worker safety

Learn more

Efficiency improvement30%

Intelligent protection and safe production

Intelligent bevel cutting head can achieve ±45° bevel cutting, forming multiple bevels at one time, doubling cutting efficiency.

Ultra high power laser cutting machine

Ground rail fiber laser cutting machine

Fully enclosed sheet laser cutting machine

Processing area

3000*1500mm

Positioning accuracy

±0.03mm

Processing area

4000*1500mm

Positioning accuracy

±0.03mm

Processing area

4000*2000mm

Positioning accuracy

±0.03mm

Processing area

6000*1500mm

Positioning accuracy

±0.03mm

Processing area

6000*2000mm

Positioning accuracy

±0.03mm

Processing area

6000*2500mm

Positioning accuracy

±0.03mm

Processing area

8000*2000mm

Positioning accuracy

±0.03mm

Processing area

8000*2500mm

Positioning accuracy

±0.03mm

Processing area

13000*2500mm

Positioning accuracy

±0.03mm

Processing area

14000*3100mm

Positioning accuracy

±0.03mm

Processing area

25000*3100mm

Positioning accuracy

±0.03mm

You will receive a response within one business day

You will receive a response within one business day