Fiber laser cutting machines demonstrate varying capabilities in processing metal sheets of different thicknesses. The maximum cutting depth depends primarily on the material type and the laser system’s power output. While high-powered 8kW systems can cut mild steel up to 30mm thick, other metals have distinct limitations. Understanding these thickness parameters proves essential for manufacturing efficiency and project planning, as material selection directly impacts production outcomes and cost-effectiveness.

Основные выводы

Modern fiber laser cutting machines with 12kW power can cut mild steel up to 30mm thick with acceptable quality.

Stainless steel cutting maxes out at 25mm for grade 304 and 20mm for grade 316L using high-power systems.

Aluminum can be cut up to 25mm thick, while copper and brass are limited to 12mm and 8mm respectively.

Optimal cutting quality occurs at 60-80% of maximum rated thickness, with diminishing results beyond these ranges.

Maximum cutting thickness varies by material type, with mild steel having the highest capacity among common metals.

Understanding Fiber Laser Technology and Power Ratings

Fiber laser technology represents a revolutionary advancement in industrial cutting applications, utilizing a high-powered beam generated by optical fibers doped with rare earth elements. These systems typically operate with power ratings ranging from 1kW to 12kW, with higher-powered machines becoming increasingly available for specialized fiber laser applications.

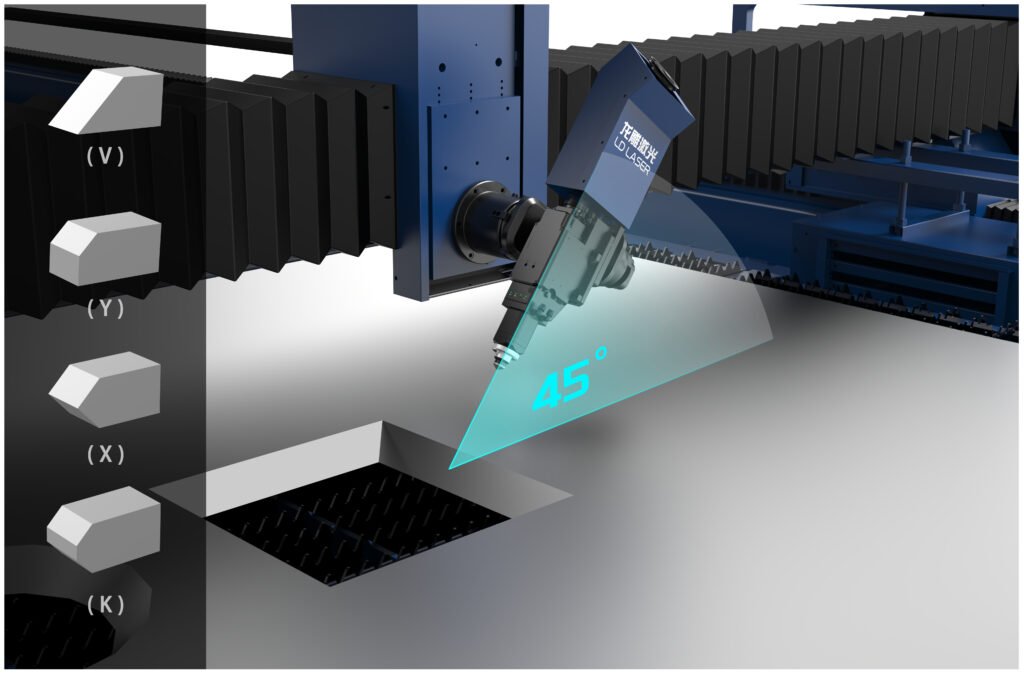

The power rating directly correlates to the machine’s cutting capabilities, particularly regarding material thickness and speed. Modern fiber lasers achieve precision cutting through a focused beam diameter of approximately 100 micrometers, delivering intense energy concentration at the cutting point. The beam quality, measured by the BPP (Beam Parameter Product), typically ranges from 0.3 to 0.4 mm*mrad, enabling superior edge quality compared to traditional cutting methods.

Power density, beam mode, and wavelength stability are essential factors affecting the system’s performance, with current technology operating at wavelengths around 1064nm for best metal processing efficiency.

Maximum Cutting Thickness for Mild Steel

The maximum cutting thickness for mild steel in fiber laser applications directly correlates with the machine’s power output, typically ranging from 2kW to 12kW in industrial systems. Surface quality requirements influence achievable thickness limits, with favorable edge quality generally possible up to 20mm for 6kW systems and 30mm for 12kW systems under ideal conditions. Industry standards indicate that most commercial fiber laser cutting operations maintain production efficiency and quality when cutting mild steel between 3mm to 25mm, depending on the specific application requirements and power capabilities.

Power Output Impact

Laser power output directly correlates with the maximum cutting thickness achievable in mild steel applications. Higher wattage fiber laser systems demonstrate enhanced capability in processing thicker materials, with power settings ranging from 2kW to 12kW commonly available in industrial applications. A 2kW system typically handles mild steel up to 12mm, while 6kW units can process up to 25mm effectively.

The relationship between power and thickness is not strictly linear, as energy efficiency plays a vital role in material penetration. Ideal cutting performance requires balancing power density, cutting speed, and assist gas pressure. Modern fiber lasers operating at 8kW or higher can achieve clean cuts in mild steel up to 30mm thick, though cutting speeds decrease markedly with material thickness increases.

Surface Quality Factors

When cutting thick mild steel with fiber lasers, surface quality depends on multiple interdependent variables including focal point position, assist gas pressure, and cutting speed refinement. The surface finish and edge quality are directly influenced by these parameters, which must be precisely controlled to achieve ideal results.

| Thickness (mm) | Surface Quality Factors | Recommended Settings |

|---|---|---|

| 1-5 | Minimal dross | High speed, low gas |

| 6-10 | Striations present | Medium speed, balanced |

| 11-15 | Roughness increases | Reduced speed, high gas |

| 16-20 | Edge oxidation risk | Slow speed, max gas |

| >20 | Quality deteriorates | Special parameters |

The achievable surface quality diminishes progressively with increased material thickness. Proper parameter adjustment becomes increasingly critical above 15mm, where maintaining consistent edge quality requires precise refinement of cutting parameters and careful monitoring of the process variables.

Common Industry Standards

While maximum cutting thickness capabilities vary among fiber laser manufacturers, industry standards generally establish 25mm as the practical limit for reliable mild steel cutting with high-powered fiber lasers operating at ideal parameters. Industry practices typically recommend maintaining cutting thicknesses between 16mm to 20mm for peak production efficiency and consistent quality output.

Material standards specify that thicknesses beyond 20mm often require reduced cutting speeds and increased laser power, potentially compromising edge quality and production rates. Most commercial fiber laser systems are calibrated to align with these industry-accepted thickness parameters, ensuring reliable performance within established tolerances. Leading manufacturers design their systems to achieve consistent cutting results within these standardized thickness ranges, particularly for mild steel applications in industrial manufacturing settings.

Stainless Steel Thickness Capabilities

Modern fiber laser cutting systems demonstrate remarkable capabilities when processing stainless steel, with maximum cutting thicknesses ranging from 20mm to 30mm depending on the power output and specific grade of material. High-powered systems operating at 12kW can effectively cut through 304 stainless steel up to 25mm thick, while 316L grades typically max out at 20mm due to their higher nickel content.

The achievable thickness varies considerably across different stainless steel grades, with austenitic varieties generally allowing for deeper cuts compared to martensitic grades. Thickness variations also depend on the cutting parameters, including assist gas pressure, cutting speed, and focal point position. For ideal results, manufacturers often recommend reducing cutting speeds by 15-20% when approaching maximum thickness capabilities. Advanced beam-shaping technology and precision gas delivery systems help maintain cut quality even at maximum thickness ranges, though edge quality may require secondary finishing at the upper limits.

Aluminum and Non-Ferrous Metal Cutting Limits

Fiber laser cutting systems demonstrate distinct thickness limitations when processing aluminum and non-ferrous metals, with maximum cutting capabilities typically ranging from 15mm to 25mm for aluminum alloys, 12mm for copper, and 8mm for brass. These limitations stem from the materials’ thermal and optical properties, which affect laser beam absorption and heat dissipation during cutting.

When processing aluminum alloys, fiber laser systems operate most efficiently on thicknesses between 3mm and 15mm, with specialized high-power systems required for greater depths. Non-ferrous applications present unique challenges due to varying reflectivity levels and thermal conductivity characteristics. Copper and brass, being highly reflective materials, require considerably higher power densities for effective cutting, which impacts maximum achievable thickness. Modern fiber laser systems employ specialized cutting parameters, including adjusted focal lengths and assist gas pressures, to optimize performance across different non-ferrous materials while maintaining cut quality and edge finish.

Key Factors Affecting Maximum Cutting Thickness

Several essential factors determine the maximum cutting thickness achievable with fiber laser systems, including laser power output, beam quality, material properties, and cutting assist gas parameters.

Higher laser power enables greater penetration depth but must be balanced with ideal beam focus and quality to maintain cutting efficiency. The material’s thermal conductivity, melting point, and surface reflectivity markedly impact maximum thickness capabilities. Assist gas pressure and type play vital roles in removing molten material and preventing oxidation.

Cutting speed must decrease proportionally as material thickness increases to maintain cut quality. The relationship between speed and thickness follows a non-linear curve, with efficiency dropping more rapidly beyond certain thickness thresholds. Beam mode quality (M²) and focal spot size become increasingly essential when processing thicker materials, as they affect the power density at the cutting zone. Modern fiber lasers typically achieve ideal laser efficiency when operating within 60-80% of their maximum rated thickness capacity.

Impact of Material Properties on Cutting Performance

Physical and chemical properties of materials greatly influence the maximum achievable cutting thickness and overall performance in fiber laser cutting operations. Material composition directly affects laser absorption rates, with different metals exhibiting varying degrees of reflectivity and thermal conductivity. For instance, stainless steel typically allows deeper cuts than aluminum due to its superior laser absorption characteristics at 1064nm wavelength.

The material’s thermal properties, including melting point and heat capacity, determine the energy required for effective cutting. Highly reflective materials like copper and brass present challenges due to lower absorption rates, necessitating higher power settings or reduced cutting speeds. Additionally, the material’s microstructure and grain orientation can impact cut quality and maximum thickness capabilities. Materials with lower thermal conductivity often permit deeper cuts as heat remains concentrated in the cutting zone, while highly conductive materials dissipate heat more rapidly, potentially limiting cutting depth.

Power Output and Its Relationship to Cutting Depth

The relationship between laser power output and cutting depth follows a generally linear correlation, though this relationship becomes more complex at higher power levels. As power increases, operators can achieve greater cutting depths while maintaining acceptable cutting speed. However, the efficiency curve begins to flatten at higher power outputs due to factors such as heat dissipation and plasma formation.

Modern fiber laser systems typically operate between 2kW and 12kW, with higher-powered machines capable of cutting thicker materials more efficiently. The energy efficiency of the cutting process depends on the ideal balance between power output and cutting speed. For instance, a 6kW system cutting 12mm steel requires different power-to-speed ratios than when cutting 3mm material. Engineers must consider that excessive power without corresponding speed adjustments can lead to deteriorating cut quality, characterized by increased dross formation and wider kerf width. This relationship ultimately determines the practical maximum thickness achievable for each material type.

Optimizing Cut Quality at Different Thicknesses

Achieving ideal cut quality across varying material thicknesses requires precise calibration of multiple laser parameters. The refinement process involves adjusting focal length, assist gas pressure, cutting speed, and power density based on specific material thickness ranges. For thin materials under 3mm, higher speeds and lower power settings typically yield superior edge quality, while thicker materials demand increased power and reduced cutting speeds.

Thickness adjustment correlates directly with beam focus position and kerf width control. Operating within the ideal cutting window for each thickness prevents common defects such as dross formation and edge roughness. Manufacturers must maintain strict parameter matrices that account for material composition and thickness variations. Testing procedures often utilize cut quality assessment methods like surface roughness measurements (Ra values) and edge perpendicularity checks to validate parameter selections. This systematic approach guarantees consistent results across production runs while maximizing the efficiency of the cutting process.

Common Industry Standards and Specifications

Industry standards for fiber laser cutting establish specific requirements and tolerances across different manufacturing sectors. The cutting industry has developed thorough guidelines that guarantee consistency and quality in fiber laser operations, particularly focusing on material-specific parameters and safety protocols.

- ISO 9013:2017 sets the classification requirements for thermal cuts, defining quality levels based on perpendicularity tolerance, surface roughness, and kerf width measurements.

- EN 1090 certification specifies execution requirements for steel structures, including precise tolerances for fiber laser cut components used in construction.

- AWS D14.1 provides standards for industrial cutting operations, detailing acceptable cut quality characteristics and dimensional accuracy requirements.

These standardized specifications enable manufacturers to maintain consistent quality levels while optimizing production efficiency. The fiber laser cutting industry regularly updates these standards to incorporate technological advancements and evolving market demands, guaranteeing compliance with international quality management systems and safety regulations.

Comparing Thickness Capabilities Across Different Laser Systems

While fiber laser systems excel at cutting thin to medium-gauge materials, CO2 and other laser variants demonstrate different ideal thickness ranges for specific applications. A thorough efficiency comparison reveals distinct capabilities across laser cutting technologies, with each system optimized for specific material thicknesses.

| Laser Type | Maximum Cutting Thickness (mm) | Material Suitability | Speed Rating | Cost Efficiency |

|---|---|---|---|---|

| Fiber Laser | 25 | Thin to Medium Metals | High | Excellent |

| CO2 Laser | 40 | Thick Metals | Medium | Good |

| Disk Laser | 32 | Medium to Thick | High | Moderate |

| Direct Diode | 15 | Thin Metals | Very High | Very Good |

| Pulsed Nd:YAG | 20 | Specialty Materials | Low | Fair |

The thickness capabilities vary markedly based on the material being processed. Fiber laser systems demonstrate superior performance in cutting materials up to 25mm thick, particularly excelling in processing reflective metals like aluminum and copper. However, for thicker materials beyond this range, CO2 lasers often provide better cutting quality and consistency.

Заключение

In the grand theater of metal fabrication, fiber laser cutting machines demonstrate their superiority with precise thickness limitations: 30mm for mild steel (8kW systems), 25mm for stainless steel, 25mm for aluminum, 12mm for copper, and a modest 8mm for brass. While manufacturers boast about maximum capabilities, ideal efficiency consistently resides within the 3-15mm sweet spot – a humbling reminder that even cutting-edge technology has its limits.