Like the precision of a Swiss timepiece, a tube laser cutting machine represents the pinnacle of modern manufacturing technology. You’ll find that these systems have revolutionized metal fabrication through their combination of accuracy, speed, and versatility. When you’re considering equipment upgrades for your production facility, understanding the key advantages of tube laser cutting machines can transform your manufacturing capabilities and give you a competitive edge in today’s demanding market.

Ključne ugotovitve

Achieves micron-level precision with tolerances down to ±0.1mm, ensuring consistently high-quality cuts and minimal material waste.

Processes multiple materials and profiles while enabling complex patterns and decorative elements impossible with traditional methods.

Operates at speeds up to 100 meters per minute with minimal setup time, enabling 24/7 automation for maximum productivity.

Reduces material waste by 30% through advanced nesting algorithms and optimized cutting paths.

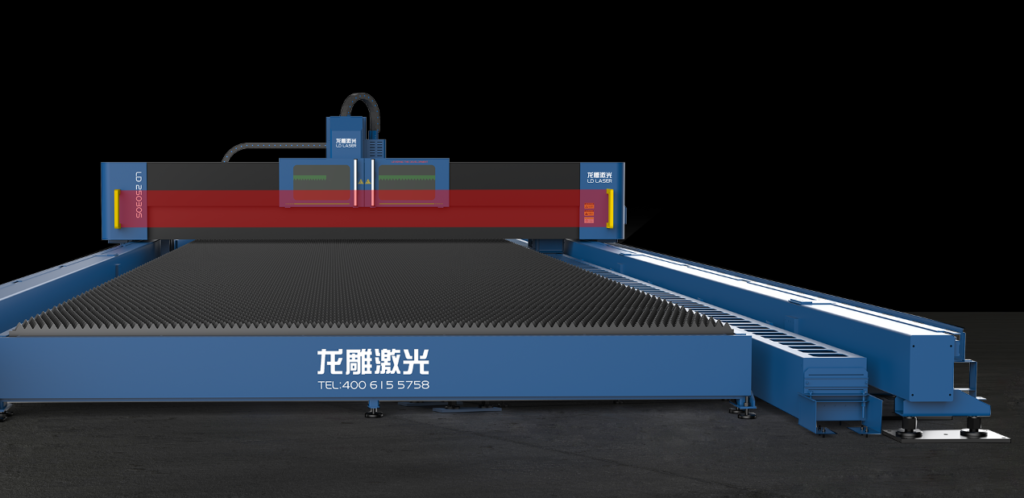

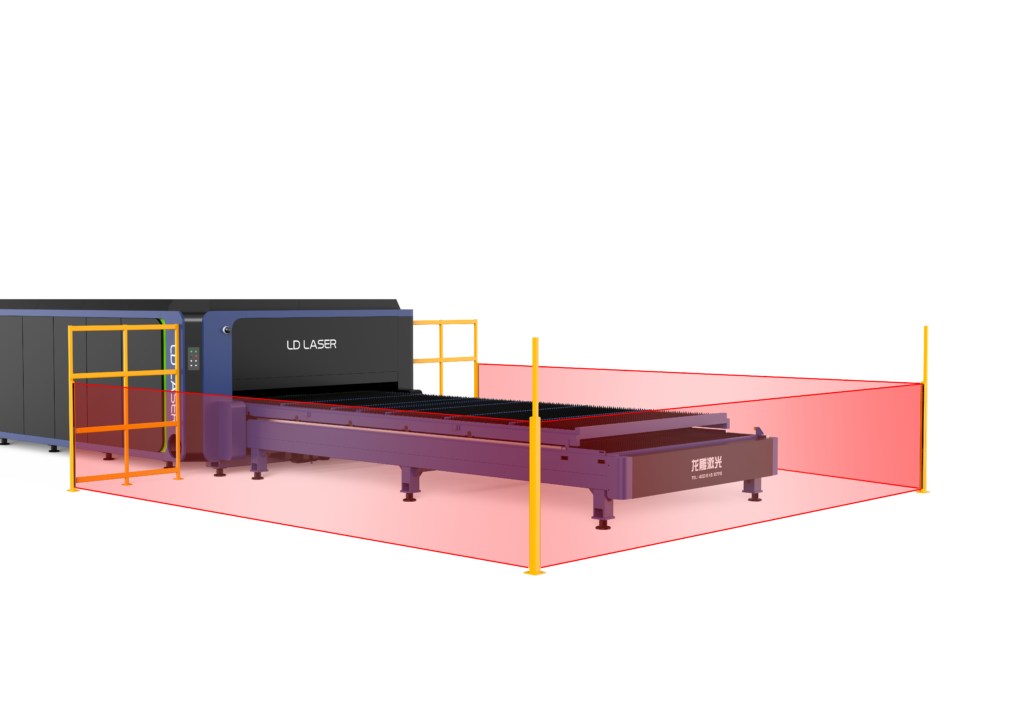

Features comprehensive safety systems including light curtains, motion sensors, and real-time monitoring for secure operation.

Superior Precision and Accuracy

Precision engineering demands tools that can deliver consistent, micron-level accuracy in metal fabrication. When you’re working with tube cutting applications, a laser cutting machine provides superior dimensional accuracy through advanced laser beam refinement and automated controls. You’ll achieve tolerances as tight as ±0.1mm, ensuring your parts meet exact specifications.

The machine’s precision alignment systems maintain perfect positioning throughout the cutting process, eliminating the variations common in traditional cutting methods. You’ll benefit from integrated measurement systems that continuously monitor and adjust the laser’s focal point, maintaining optimal beam characteristics. This level of accuracy proves especially important when you’re producing complex geometries, interlocking components, or parts requiring precise fit-and-finish. The result is consistently high-quality cuts with minimal material waste and reduced need for secondary operations.

Faster Production Speeds

While traditional cutting methods often require multiple passes or slower feed rates, tube laser cutting machines dramatically accelerate production throughput with cutting speeds up to 100 meters per minute. You’ll achieve superior production efficiency through automated material handling, rapid processing cycles, and minimal setup time between jobs.

| Speed Factor | Performance | Impact |

|---|---|---|

| Feed Rate | 100m/min | Higher throughput |

| Setup Time | 2-3 min | Reduced downtime |

| Processing | Single-pass | No rework needed |

| Automation | 24/7 capable | Maximum uptime |

The laser speed capabilities allow you to process complex geometries in a fraction of the time compared to mechanical cutting methods. You’ll notice immediate improvements in your production schedules, with some operations reporting efficiency gains of up to 300% after implementing tube laser technology.

Cost-Effective Material Usage

Na spletni strani . advanced nesting algorithms in . optimizirane poti rezanja, tube laser machines minimize material waste by efficiently arranging parts across the raw stock. You’ll find that these systems automatically calculate the most effective way to utilize every inch of tubing, reducing scrap rates by up to 30% compared to traditional cutting methods.

The machine’s optimization strategies guarantee you’re maximizing your resource management by precisely controlling cut quality and material usage. You’ll benefit from the system’s ability to process multiple parts from a single tube section, while maintaining tight tolerances and exact specifications. The software’s intelligent planning features help you track material inventory, forecast usage requirements, and analyze yield rates in real-time, enabling you to make data-driven decisions about your production processes and material purchases.

Versatile Material Processing Capabilities

Modern stroji za laserski razrez cevi excel at processing diverse material types, ranging from standard carbon steel and stainless steel to aluminum, brass, copper, and specialized alloys. You’ll find the technology adapts seamlessly to varying material thicknesses and compositions, enabling innovative applications across multiple industries.

These machines can handle round, square, rectangular, and oval tube profiles with consistent precision. You’re able to process both thin-walled decorative pieces and thick-walled structural components, demonstrating remarkable industry adaptability. The system’s advanced cutting parameters automatically adjust to accommodate different material properties, ensuring ideal results whether you’re working with highly reflective metals or heat-sensitive materials. This versatility allows you to expand your manufacturing capabilities and take on complex projects that require multiple material types without changing equipment.

Reduced Post-Processing Requirements

Because tube laser cutting delivers exceptionally čisti rezi and precise edges, you’ll notice a significant reduction in post-processing requirements compared to traditional cutting methods. You’ll save considerable time and resources by eliminating many secondary operations like deburring, grinding, and edge finishing.

The high-precision laser beam guarantees material cleanliness by minimizing heat-affected zones and preventing slag formation. Your parts will emerge with smoother surfaces and more accurate dimensions, reducing the need for extensive post processing techniques. This streamlined approach means you can move directly to welding, painting, or assembly operations in many cases. Additionally, you’ll experience fewer material handling steps, decreased labor costs, and reduced risk of part damage that often occurs during manual finishing processes. The result is a more efficient production cycle with enhanced part quality.

Automated Operation Benefits

While reduced post-processing streamlines manual operations, automated tube laser cutting systems take efficiency to the next level. You’ll benefit from automated workflows that minimize human intervention, reducing errors and increasing production consistency. The machine’s software can enhance cutting sequences, material utilization, and tool paths automatically.

These systems enable you to load CAD files directly into the machine, where intelligent algorithms determine the most efficient cutting strategy. You’ll see significant efficiency improvements through avtomatizirano ravnanje z materialom, where the system can load, position, and unload tubes without operator intervention. The machine can also automatically adjust cutting parameters based on material properties and thickness, ensuring peak results. This automation reduces setup time, increases throughput, and allows your skilled workers to focus on higher-value tasks.

Complex Design Possibilities

Tube laser cutting machines enable you to create complex 3D shapes with precise angles, curves, and intersecting cuts that weren’t possible with traditional cutting methods. You’ll achieve intricate patterns through the machine’s ability to rotate and manipulate tubular materials while maintaining tight tolerances and clean edges. The system’s advanced software lets you design and execute sophisticated geometric patterns, lattices, and decorative elements across cylindrical surfaces with exceptional accuracy.

3D Shaping Capabilities

Through advanced D shaping capabilities, tube laser cutting machines can transform cylindrical materials into complex geometric profiles with exceptional precision. You’ll gain unique design flexibility to create D-shaped profiles that combine flat and curved surfaces within a single workpiece. The machine’s efficient shape customization allows you to precisely control the depth, angle, and position of flat surfaces on round tubes.

| Funkcija | Capability | Application |

|---|---|---|

| Depth Control | 0.1-100mm | Mechanical Fits |

| Surface Finish | Ra 0.8-3.2 | Aesthetic Quality |

| Angular Precision | ±0.1° | Joint Assembly |

| Position Accuracy | ±0,05 mm | Critical Mating |

| Process Speed | Up to 30m/min | Production Rate |

The D shaping functionality enables you to create flat mounting surfaces, precise mechanical interfaces, and complex geometrical features that integrate seamlessly with other components in your assembly designs.

Intricate Pattern Generation

Beyond basic cutting operations, modern tube laser systems excel at generating intricate patterns in . complex geometric designs across cylindrical surfaces. You’ll find remarkable design flexibility that enables detailed artistic applications across various tubular materials. The precision control and advanced software capabilities let you create elaborate patterns that would be impossible with traditional cutting methods.

- Seamlessly produce decorative perforations, lattices, and geometric shapes with microscopic accuracy and consistent repeatability

- Transform simple tubes into sophisticated architectural elements featuring custom logos, text, or artistic motifs

- Execute complex cut-outs and overlapping designs while maintaining structural integrity and material strength

These intricate pattern capabilities make tube laser systems invaluable for both functional and aesthetic applications, from industrial components to high-end architectural features.

Enhanced Safety Features

While traditional metal cutting poses numerous workplace hazards, modern tube laser cutting machines incorporate sophisticated safety mechanisms that greatly reduce operational risks. You’ll find thorough safety technology features that protect operators through multiple layers of protection, from emergency stops to light curtains. Proper operator training guarantees these systems are utilized effectively.

| Safety Feature | Function | Protection Level |

|---|---|---|

| Light Curtains | Stops beam if breached | Primary |

| Emergency Stops | Immediate shutdown | Critical |

| Enclosed Cabinet | Contains radiation | Essential |

| Motion Sensors | Detects movement | Secondary |

Your machine’s integrated safety systems monitor operations continuously, automatically shutting down if they detect anomalies in cutting parameters or unauthorized access attempts. These advanced features make tube laser cutting much safer than conventional cutting methods while maintaining peak productivity.

Zaključek

Ugotovili boste, da stroji za laserski razrez cevi revolutionize your manufacturing workflow like a skilled medieval blacksmith equipped with modern precision tools. The combination of ±0.1mm tolerances, 100-meter-per-minute processing speeds, and 30% material savings delivers quantifiable ROI. These systems’ automated operations, multi-material capabilities, and integrated safety protocols transform complex designs into efficiently manufactured components while maintaining strict quality parameters.