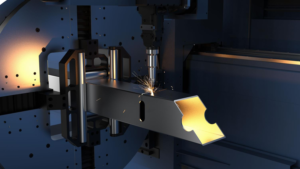

Like a precision surgeon transforming raw material into art, tube laser cutting technology can revolutionize your manufacturing process. You’ll discover how this advanced equipment delivers eşsiz doğruluk down to ±0.1mm while dramatically reducing operational costs. From automated production sequences to material optimization, the adoption of tube laser cutting machines offers a compelling range of benefits that’ll reshape your manufacturing capabilities and competitive edge.

Önemli Çıkarımlar

Tube laser cutting machines deliver exceptional precision with tolerances of ±0.1mm, reducing waste and eliminating secondary operations.

Automated operation significantly reduces labor costs while increasing production speed through continuous, efficient processing.

Smart nesting algorithms maximize material utilization up to 95%, minimizing waste and lowering overall production costs.

The machines process multiple materials and tube profiles, enabling quick design modifications and rapid prototyping capabilities.

Integration with workflow systems and real-time monitoring ensures consistent quality while enabling 24/7 operation for maximum ROI.

Precision and Accuracy in Complex Tube Cutting Operations

When performing complex tube cutting operations, tüp lazer kesim makineleri deliver unprecedented levels of precision and accuracy that surpass traditional cutting methods. You’ll achieve tolerances as tight as ±0.1mm through advanced laser alignment techniques that automatically adjust to variations in material thickness and composition. These machines utilize sophisticated tube geometry analysis to guarantee precise cutting angles and maintain dimensional stability throughout the process.

You can expect consistent results across multiple production runs, as the machine’s integrated sensors continuously monitor and adjust cutting parameters in real-time. The system’s ability to perform intricate cuts, including bevels, slots, and complex hole patterns, eliminates the need for secondary operations. This enhanced precision not only improves part quality but also reduces material waste and rework requirements.

Cost Reduction Through Automated Production

The implementation of automated tube laser cutting systems directly translates precision capabilities into measurable cost savings. You’ll find that automation benefits extend beyond reduced labor costs, as these systems minimize material waste through optimized nesting and cutting patterns. Your operasyonel veri̇mli̇li̇k increases considerably when you eliminate manual setup time and reduce the need for secondary finishing operations.

You can achieve substantial savings through faster production cycles, as automated systems operate continuously with minimal downtime. By integrating tube laser cutting into your workflow, you’ll decrease inventory costs through just-in-time manufacturing capabilities. The reduction in human error and consistent quality output means you’ll spend less on rework and scrap materials. These combined efficiencies create a compelling return on investment that strengthens your competitive position in the market.

Increased Production Speed and Efficiency

Your tube laser cutting machine’s automated material handling system will streamline the production process by eliminating manual loading and unloading steps. You’ll notice significant time savings as the machine efficiently processes tubes and pipes without operator intervention between cuts. The reduced handling time, combined with the machine’s rapid cutting capabilities, allows you to complete projects faster while maintaining consistent quality across all workpieces.

Automated Material Handling

Modern tube laser cutting machines incorporate sophisticated automated material handling systems that revolutionize production workflows. You’ll find that these systems seamlessly load, position, and unload tubes without manual intervention, greatly reducing operator fatigue and potential handling errors.

Through automated integration, your production line can maintain continuous operation with minimal downtime. The handling efficiency is enhanced by intelligent feed systems that automatically adjust to different tube sizes and shapes. You can program the machine to sort and stack finished pieces, while smart sensors monitor material flow and prevent collisions.

Your facility benefits from reduced labor costs and improved workplace safety, as workers no longer need to manually manipulate heavy materials. The system’s precision positioning guarantees consistent quality across all cuts, maintaining tight tolerances throughout your production run.

Reduced Production Time

Building upon automated handling capabilities, tube laser cutting machines deliver exceptional production speeds that dramatically reduce manufacturing time. You’ll experience significant lead time reduction as these systems can process complex cuts in seconds rather than minutes required by traditional methods. The immediate shift between different cutting operations eliminates setup delays and tool changes.

Your workflow optimization improves through simultaneous operations, where the machine can cut multiple features while rotating the tube in a single setup. The precision cutting head moves at high speeds along multiple axes, completing intricate patterns without sacrificing accuracy. By eliminating secondary operations and reducing manual intervention, you’ll achieve faster throughput and shorter production cycles. This enhanced efficiency allows you to handle more orders and meet tighter deadlines while maintaining consistent quality standards.

Minimizing Material Waste and Scrap

Advanced tube laser cutting systems excel at minimizing malzeme atığı through precise programming and intelligent nesting algorithms. You’ll achieve superior material efficiency by optimizing the placement of parts on your raw stock, enabling you to utilize up to 95% of available tube material. The system’s software automatically calculates the most efficient cutting patterns while considering factors like kerf width and part spacing.

Versatility in Material Processing Capabilities

While traditional cutting methods may be limited to specific materials, tüp lazer kesim makineleri offer exceptional flexibility across a wide spectrum of metals and alloys. You’ll find these machines can efficiently process stainless steel, mild steel, aluminum, brass, copper, and various exotic metals with precision and consistency.

Beyond the diverse material types, you’re able to handle different tube profiles including round, square, rectangular, and oval configurations. The advanced processing techniques allow you to cut materials of varying thicknesses, from thin-walled tubes to heavy-duty structural components. You can seamlessly switch between material types without significant machine modifications or tooling changes. This versatility extends to the ability to perform complex cuts, bevels, and intricate patterns on different materials while maintaining tight tolerances and superior edge quality.

Enhanced Design Flexibility and Customization

You’ll discover that tüp lazer kesim makineleri excel at producing complex geometries with unprecedented precision and ease, eliminating many traditional manufacturing constraints. Your design iterations can move from concept to production faster, as these machines directly translate CAD files into cutting paths without requiring extensive tooling changes or setups. The technology’s ability to create unlimited shape configurations enables you to customize your tubular components with intricate cutouts, complex joint designs, and precise dimensional specifications that meet your exact requirements.

Complex Geometries Made Simple

Because tüp lazer kesim makineleri operate with remarkable precision along multiple axes, they excel at producing karmaşık geometrik desenler and shapes that would be impossible or impractical with traditional cutting methods. You’ll find that intricate cuts, bevels, and contours can be executed with olağanüstü doğruluk, eliminating many technical challenges that typically arise in conventional manufacturing processes.

These machines enable you to tackle design innovation without the constraints of manual cutting limitations. You can create complex intersections, lattice structures, and detailed cutouts while maintaining consistent quality across your production runs. Whether you’re working with round, square, or rectangular tubing, the machine’s advanced programming capabilities let you achieve precise angles, curves, and joints that would otherwise require multiple setup operations and specialized tooling.

Faster Design Iterations Possible

Modern tüp lazer kesim makineleri dramatically accelerate the design iteration process through seamless CAD/CAM integration ve rapid prototyping capabilities. You’ll be able to quickly test tasarım konseptleri, make adjustments, and validate solutions without the lengthy setup times associated with traditional tooling methods.

When you need to modify your tube designs, you can implement changes directly in your CAD software and send updated files to the laser cutting machine. This streamlined workflow enables you to receive design feedback within hours instead of weeks. The rapid prototyping capabilities allow you to verify form, fit, and function of complex tubular components before committing to full production runs. You can efficiently explore multiple design variations, optimize material usage, and respond to customer requirements with greater agility and precision.

Unlimited Shape Configurations

The exceptional design flexibility of tube laser cutting machines opens up virtually limitless shape configurations that weren’t previously achievable through conventional fabrication methods. You’ll discover unprecedented creative design possibilities when working with these advanced systems, enabling you to produce intricate components that meet exact specifications.

Consider these key shape manipulation capabilities:

- Complex shapes with multiple cutouts, slots, and tabs can be produced in a single setup without requiring additional tooling or secondary operations

- Precise angles, curves, and bevels can be cut directly into tubes of varying diameters and wall thicknesses

- Custom joint configurations and interlocking features can be incorporated seamlessly, allowing for innovative assembly methods

This versatility lets you push the boundaries of traditional tube fabrication while maintaining sıkı toleranslar and superior edge quality.

Quality Control and Consistency in Output

While traditional tube cutting methods often produce inconsistent results, tüp lazer kesim makineleri deliver precise, repeatable outcomes through advanced quality control systems. You’ll find that these machines incorporate real-time monitoring features that guarantee output consistency throughout your production runs. The integrated quality assurance protocols automatically detect and adjust for material variations, maintaining dimensional accuracy within microns.

Your operators can set specific parameters for each cut, and the machine’s sophisticated software will maintain these exact specifications across thousands of pieces. The system’s automated inspection capabilities instantly flag any deviations from predetermined tolerances, reducing waste and eliminating the need for manual quality checks. This level of precision guarantees that you’ll achieve identical parts every time, meeting the strictest industry standards and customer specifications.

Streamlined Production Workflow

Building upon these quality control advantages, tube laser cutting machines revolutionize production workflows through otomati̇k malzeme taşima and processing sequences. You’ll experience significant workflow optimization when your system integrates seamlessly with existing production lines, reducing manual intervention and bottlenecks.

Process integration becomes more efficient through:

- Automated loading and unloading systems that synchronize with your warehouse management software

- Real-time production scheduling that adjusts cutting parameters based on material specifications and order requirements

- Direct communication between CAD/CAM systems and the machine’s control interface, eliminating programming delays

These streamlined operations minimize downtime between jobs and maximize your throughput capacity. By connecting various production stages through integrated controls, you’ll reduce material handling time and achieve faster turnaround on custom orders while maintaining consistent quality standards.

Return on Investment and Long-Term Value

Investment analysis shows that tüp lazer kesim makineleri deliver substantial financial returns through multiple revenue streams and cost reductions. You’ll recover your initial investment through decreased labor costs, azaltılmış malzeme atığı, and minimized post-processing requirements. The automation capabilities enable 24/7 operation, maximizing your production capacity and throughput.

Long-term savings accumulate through lower maintenance needs, reduced tooling expenses, and decreased energy consumption compared to traditional cutting methods. You’ll benefit from improved quote competitiveness and the ability to take on complex projects that were previously outsourced. The machine’s precision and reliability translate into fewer rejected parts and warranty claims, while its versatility allows you to expand into new market segments, creating additional revenue opportunities. The technology’s future-proof nature guarantees sustained competitive advantage in the evolving manufacturing landscape.

Sonuç

By integrating tüp lazer kesim makineleri into your manufacturing process, you’ll achieve a measurable competitive advantage. Studies show that automated tube laser systems reduce malzeme atığı by up to 42% compared to traditional cutting methods, directly impacting your bottom line. When you combine this efficiency with enhanced precision, faster production speeds, and streamlined workflows, you’re positioning your operation for sustainable growth in today’s precision-driven market.