Recent industry reports show that the tube laser cutting market has grown by 8.4% annually since 2018, driven by demand for precise, automated manufacturing solutions. You’ll find that mastering this technology requires understanding both fundamental principles and cutting-edge innovations. From selecting ideal cutting parameters to managing complex geometries, there’s a systematic approach you’ll need to follow. Let’s explore the technical aspects that separate basic operators from true specialists.

Önemli Çıkarımlar

Master precise parameter control including cutting speed, laser power, and assist gas pressure for optimal cutting performance.

Ensure proper beam alignment and focal length maintenance through regular monitoring and calibration of the laser system.

Understand material-specific requirements and adjust cutting parameters accordingly for stainless steel, aluminum, and mild steel.

Implement systematic quality control checkpoints and maintain detailed documentation of cutting processes and troubleshooting solutions.

Develop expertise in multi-axis operations and dynamic focusing systems for complex geometric cuts and varying material thicknesses.

Tüp Lazer Kesim Teknolojisini Anlamak

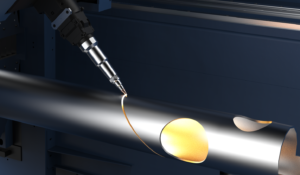

While conventional laser cutting focuses on flat sheets, tüp lazer kesim employs specialized technology to cut complex profiles in cylindrical and rectangular tubing. In this process, you’ll find that the laser beam precisely cuts through the material while the tube rotates, allowing for intricate patterns and shapes that would be impossible with traditional methods.

You’ll need to understand that the cutting process involves sophisticated motion control systems that synchronize the movement of both the laser head and the workpiece. The technology uses advanced sensors and software to maintain consistent focal length and beam alignment throughout the operation. This guarantees clean, accurate cuts even when dealing with varying tube diameters and wall thicknesses. The system compensates for material variations and automatically adjusts parameters to maintain ideal cutting conditions.

Essential Parameters for Optimal Cut Quality

Achieving ideal cut quality in tube laser cutting requires precise control of several critical parameters. You’ll need to carefully adjust your cut speed based on material thickness and type, as faster isn’t always better. Maintain optimal beam focus to guarantee the laser’s energy concentrates precisely at the cutting point.

Monitor your assist gas pressure and flow rate, as they directly impact edge quality and dross formation. You’ll want to match your laser power settings to both the material properties and cutting requirements. The focal position must remain consistent throughout the process, especially when working with varying tube geometries.

Remember to keep your standoff distance steady and adjust your nozzle configuration according to the specific application. These parameters work together synergistically to produce clean, precise cuts.

Common Materials and Their Cutting Requirements

Different materials present unique challenges and requirements in tube laser cutting operations. You’ll need to adjust your cutting parameters based on the specific material properties and thickness you’re working with.

| Material | Cutting Speed (m/min) | Assist Gas |

|---|---|---|

| Stainless Steel | 8-12 | Nitrogen |

| Aluminum Alloys | 15-20 | Nitrogen |

| Mild Steel | 10-15 | Oxygen |

When cutting stainless steel tubes, you’ll achieve ideal results using nitrogen as an assist gas to prevent oxidation and maintain clean edges. Aluminum alloys require higher cutting speeds and specific power settings to prevent material melting issues. You’ll need to carefully control the focal position and gas pressure to achieve clean cuts, particularly with reflective materials. Each material demands precise parameter adjustment to guarantee consistent quality and minimize post-processing requirements.

Troubleshooting and Quality Control Measures

To maintain consistent quality in tube laser cutting operations, you’ll need to implement systematic troubleshooting procedures ve quality control protocols. Monitor your beam parameters regularly and address laser alignment issues promptly to prevent defects in the final product. Check for material inconsistencies before processing, as variations in thickness or composition can affect cut quality.

Establish quality checkpoints throughout your production process, including pre-cutting material inspection, in-process monitoring, and post-cut evaluation. Measure cut edges for straightness, perpendicularity, and surface roughness. Document any deviations and maintain a database of common issues and their solutions. Regular calibration of your laser cutting system’s optical components and mechanical assemblies will help guarantee peak performance. When problems arise, systematically isolate variables to identify root causes quickly.

Advanced Techniques and Industry Applications

Bir yandan traditional tube laser cutting serves many basic manufacturing needs, advanced techniques have emerged to tackle more complex geometric challenges and specialized industrial applications. You’ll find these methods particularly valuable in aerospace, automotive, and medical device manufacturing, where intricate geometries and tight tolerances are essential.

Modern tube laser cutting relies heavily on precision alignment systems and software optimization to achieve complex angular cuts and detailed patterns. You can now execute multi-axis cutting operations that weren’t possible with conventional methods. These advanced capabilities enable you to create intricate joint designs, specialized end preparations, and complex tubular assemblies.

When you’re working with advanced applications, you’ll need to utilize dynamic focusing systems and adaptive cutting parameters to maintain consistent quality across varying material thicknesses and compositions. This technology allows for seamless integration with automated production lines and smart manufacturing systems.

Sonuç

You’ll find that mastering tüp lazer kesim requires meticulous attention to process parameters and material-specific considerations. Recent industry data shows that optimized tube laser systems can achieve cutting speeds up to 100 meters per minute on thin-walled stainless steel, representing a 40% efficiency increase over conventional methods. By maintaining precise control over beam focus, assist gas pressure, and cutting speed, you’ll consistently produce high-quality components that meet strict industry specifications.