Like a surgeon’s scalpel carving with precision, a laser cutting machine serves as your gateway to precise material manipulation. You’ll find these machines transforming raw materials into intricate components across multiple industries, from automotive parts to artistic designs. Whether you’re working with metal, wood, plastic, or fabric, laser cutters offer unmatched accuracy and versatility. To fully harness their potential, you’ll need to understand their core functions and applications.

Key Takeaways

Laser cutting machines create precise cuts in materials like metal, wood, and plastic for manufacturing parts and components.

They produce intricate designs for jewelry, signs, and artistic pieces with exceptional accuracy and minimal material waste.

Medical device manufacturers use laser cutters to create surgical instruments and implants that meet strict sterilization requirements.

The automotive and aerospace industries utilize laser cutting for producing body panels, brackets, and structural components.

Laser cutters enable rapid prototyping and customization of products across industries, from electronics to furniture design.

Types of Laser Cutting Machines

Laser cutting technology encompasses three main machine types: CO2, fiber, and crystal lasers. Each type serves specific applications based on its wavelength and power characteristics.

You’ll find CO2 lasers ideal for processing non-metal materials like wood, acrylic, and textiles. These machines generate their beam through a gas mixture and typically operate at 10.6 micrometers wavelength, making them perfect for organic materials and plastics.

Fiber lasers excel at cutting metals, from thin sheets to thick plates. They’re maintenance-free and energy-efficient, using optical fibers doped with rare earth elements to generate the cutting beam. You can rely on fiber lasers for precise cuts in stainless steel, aluminum, and brass.

Crystal lasers, particularly Nd:YAG types, offer a middle ground. They’re effective for both metal and non-metal materials, though they’re less common in industrial settings due to higher maintenance requirements and operating costs.

Key Components and Working Mechanism

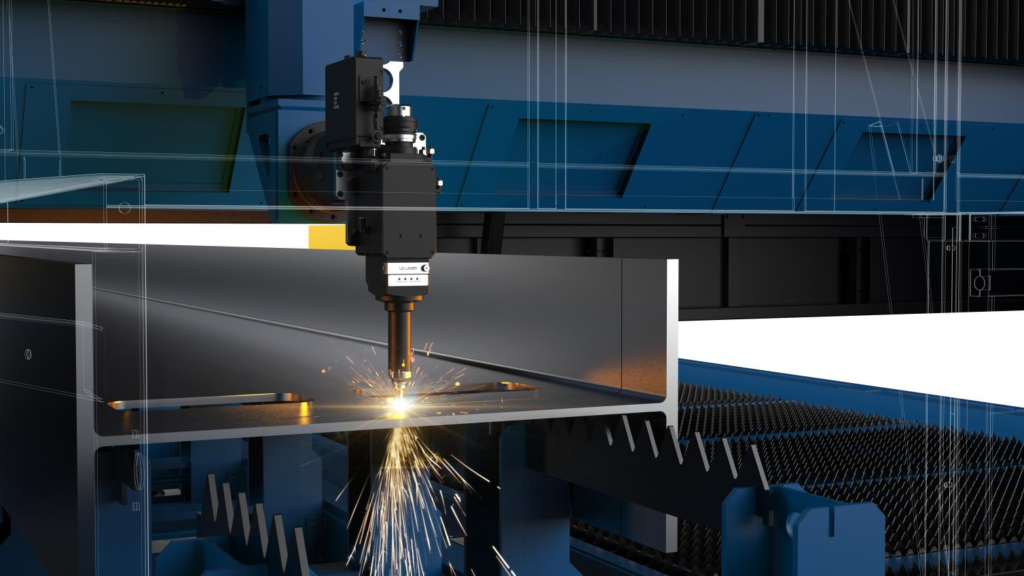

The key components you’ll find in a laser cutting machine include a laser resonator, beam delivery system, motion control system, and cutting head assembly. You’ll observe these components working together systematically: the resonator generates the laser beam, the delivery system directs it through mirrors and lenses, and the motion control system guides the cutting head precisely across the workpiece. The cutting process occurs when the focused laser beam, concentrated through the cutting head’s nozzle, heats the material to its melting or vaporization point while assist gas removes the molten material.

Essential Laser System Parts

Modern laser cutting systems comprise several essential components that work together to produce precise cuts. You’ll find these core elements across different laser system types, from CO2 to fiber lasers, regardless of their specific laser cutting applications.

The primary components include the laser resonator, which generates the focused beam; the beam delivery system, consisting of mirrors and lenses that guide the laser; and the motion control system that directs the cutting head. You’ll also need a cutting head assembly with focusing optics, an assist gas delivery system to aid cutting, and a CNC controller that coordinates all movements. The system’s cooling unit maintains ideal operating temperatures, while the exhaust system removes fumes and particles generated during cutting operations.

How Laser Cutting Works

Understanding how laser cutting works requires familiarity with its fundamental operating principle: concentrated light energy converts into heat that precisely melts, burns, or vaporizes material while a high-pressure assist gas removes the molten material.

When you’re operating a laser cutter, the system focuses a high-powered laser beam through a lens onto your workpiece’s surface. The beam’s intensity creates a localized heat zone that reaches temperatures exceeding 20,000°C. As laser technology advancements continue, you’ll find enhanced laser cutting efficiency through improved beam quality and power control. The machine’s CNC system guides the laser along your predetermined cutting path, while the assist gas – typically nitrogen or oxygen – blows away molten material and provides additional chemical reactions to aid the cutting process.

Industrial Manufacturing Applications

Industrial applications of laser cutting machines span multiple manufacturing sectors, where they perform precise material processing tasks with exceptional speed and accuracy. You’ll find these machines driving production in automotive manufacturing, aerospace components, and consumer electronics, reflecting current laser cutting trends across diverse market applications.

| Industry | Applications | Materials |

|---|---|---|

| Automotive | Body panels, brackets | Steel, aluminum |

| Aerospace | Wing components, panels | Titanium, composites |

| Electronics | Circuit boards, housings | Copper, plastics |

| Medical | Surgical tools, implants | Stainless steel, ceramics |

| Construction | Structural elements, fixtures | Steel, glass |

When you’re operating in high-volume manufacturing environments, laser cutters deliver consistent quality while minimizing material waste. They excel in creating intricate patterns and precise cuts that traditional methods can’t match. These systems integrate seamlessly with automated production lines, enhancing manufacturing efficiency through computer-controlled operations and rapid prototype development.

Architectural Design and Construction

Laser cutting machines have revolutionized architectural design by enabling complex geometric patterns and precise structural elements that weren’t feasible with traditional fabrication methods. You’ll find these machines creating intricate facade panels, decorative screens, and custom building components with unmatched laser precision.

In modern construction, you can utilize laser cutters to fabricate precise architectural models, detailed mockups, and full-scale building elements. They’re particularly valuable for creating custom metal panels, signage, and decorative installations that enhance building aesthetics. You’ll appreciate their ability to cut various materials like steel, aluminum, acrylic, and wood with exceptional accuracy.

The technology allows you to transform digital designs into physical components quickly, reducing production time and costs. You can create sophisticated architectural features such as latticed screens, perforated metals, and custom lighting fixtures that integrate seamlessly into contemporary building designs.

Automotive Parts Production

The automotive industry relies heavily on laser cutting machines for producing precise components and custom parts at scale. You’ll find these machines instrumental in automotive prototyping and manufacturing processes where precision cutting is essential for creating intricate parts that meet strict industry standards. Modern laser cutting technology guarantees consistent quality while reducing material waste and production time.

- Engine components requiring tight tolerances and complex geometries

- Custom body panels and structural elements for specialty vehicles

- Interior trim pieces and dashboard components

- Exhaust system components including manifolds and catalytic converter housings

- Specialized brackets and mounting hardware for various automotive systems

When you’re working with automotive parts production, laser cutting machines offer superior edge quality and dimensional accuracy. They’re particularly valuable for rapid prototyping new designs and creating replacement parts. The technology’s ability to cut various materials, from steel to aluminum, makes it indispensable in modern automotive manufacturing processes.

Jewelry Making and Metal Art

Modern jewelry makers and metal artists have embraced laser cutting technology to achieve intricate designs that would be challenging or impossible with traditional tools. You’ll find this technology particularly useful for creating precise patterns in metals like silver, gold, and platinum, while maintaining consistent quality across multiple pieces.

When you’re working with laser cutters in jewelry making, you can incorporate various design techniques such as filigree work, geometric patterns, and personalized engravings. The technology excels at producing layered pieces and intricate pendants with minimal material waste. You can also use laser cutting for gemstone engraving, creating custom settings, and developing unique signature collections.

The precision of laser cutting allows you to experiment with complex designs while maintaining tight tolerances. You’ll be able to produce detailed components for bracelets, earrings, and necklaces, ensuring each piece meets exact specifications and professional standards.

Sign Making and Display Solutions

You’ll find laser cutting machines indispensable for creating dimensional lettering with exact measurements and clean edges for professional signage. The technology enables you to cut and engrave acrylic, wood, and metal components precisely for LED light box assembly. Your custom light boxes can incorporate intricate designs, multiple layers, and precise apertures for ideal illumination distribution.

Precision Dimensional Lettering

When creating dimensional lettering for signs and displays, laser cutting machines deliver exceptional precision and versatility across multiple materials. You’ll achieve professional-grade dimensional design through advanced lettering techniques that guarantee perfect spacing, alignment, and depth control.

- Cut intricate letterforms from acrylic, wood, metal, or composite materials with precise edge finishing

- Create multi-layered dimensional letters by combining different material thicknesses

- Produce consistent letter sets with exact measurements for repeatable results

- Execute complex typography with sharp corners and smooth curves

- Generate custom fonts and letterforms tailored to specific brand requirements

The laser’s focused beam allows you to maintain tight tolerances while cutting both individual letters and complete sign layouts. You can quickly adjust designs digitally and produce lettering that meets exact dimensional specifications for professional signage applications.

LED Light Box Fabrication

Laser cutting machines excel at fabricating LED light box components, allowing you to create illuminated displays with precise fit and ideal light diffusion. You’ll achieve clean-cut acrylic faces, precisely spaced mounting holes, and exact channel letter backing plates essential for professional LED sign fabrication.

When you’re crafting illuminated display制作, you can use the laser cutter to create internal diffusion layers that optimize light distribution and eliminate hot spots. The machine allows you to cut precise ventilation patterns that prevent heat buildup while maintaining structural integrity. You can also engrave surface textures onto acrylic panels to enhance light dispersion and achieve specific visual effects. The technology guarantees consistent spacing between LED modules and their mounting surfaces, resulting in uniform illumination across the entire display.

Textile and Fabric Cutting

In the textile industry, laser cutting machines have revolutionized fabric processing through their ability to precisely cut, mark, and engrave a wide range of materials. You’ll find these systems particularly effective for creating intricate fabric patterns and managing complex textile applications with exceptional accuracy and speed.

When you’re working with textiles, laser cutters offer several distinct advantages:

- Sealed, fray-free edges that don’t require additional finishing

- Perfect replication of complex patterns across multiple fabric layers

- Contactless cutting that prevents material distortion

- Ability to process both natural and synthetic materials

- Automated processing for high-volume production runs

You can use laser cutting technology on various fabrics, from delicate silk to heavy canvas. The precision of the laser beam guarantees clean cuts while simultaneously sealing the edges of synthetic materials, preventing fraying. This technology’s versatility allows you to create everything from haute couture designs to mass-produced garments with consistent quality and minimal waste.

Furniture Design and Production

Laser cutting machines allow you to create precise wood pieces for custom furniture designs with tolerances down to fractions of a millimeter. You’ll achieve intricate patterns and joints that would be difficult or impossible to replicate using traditional woodworking methods. These machines excel at producing decorative inlays, precise joinery components, and complex geometric patterns that elevate the aesthetic and structural qualities of furniture pieces.

Precision Custom Wood Pieces

Modern furniture designers rely heavily on laser cutting technology to create precise, custom wood pieces that elevate their craft. You’ll find that laser cutting enables custom wood engraving with unprecedented accuracy, allowing for intricate designs that would be difficult to achieve through traditional methods.

- Achieve precise cuts with tolerances as small as 0.1mm for perfect joints and fitting

- Create complex patterns and geometric designs with consistent repeatability

- Execute detailed inlays by cutting multiple wood species to exact specifications

- Engrave surface textures and decorative elements with varying depths

- Produce uniform components for mass customization of furniture pieces

The technology’s precision guarantees each piece meets exact specifications while maintaining wood integrity. You can seamlessly integrate cut pieces into larger assemblies, knowing they’ll fit perfectly every time.

Detailed Pattern Creation

The versatile capabilities of laser cutting technology revolutionize pattern creation in furniture design, enabling you to develop intricate geometric motifs and repeating designs with unmatched precision. You’ll find that advanced engraving techniques allow for detailed pattern work on various wood species, from delicate filigree to complex tessellations.

When you’re working with laser cutting machines, you can create intricate design possibilities that would be nearly impossible to achieve through traditional woodworking methods. You’ll have control over pattern depth, spacing, and consistency across large surfaces. The technology lets you incorporate detailed inlays, decorative borders, and custom textures into your furniture pieces. By adjusting power and speed settings, you can achieve different pattern depths and create multi-layered designs that add visual interest to your furniture projects.

Medical Device Manufacturing

Medical device manufacturing demands exceptional precision and consistency, making laser cutting an invaluable fabrication method. You’ll find this technology particularly essential in creating surgical instruments and implantable devices where even microscopic variations can impact patient outcomes. The process guarantees sterile production conditions and maintains tight tolerances throughout manufacturing.

- Achieves clean, precise cuts for intricate stent designs and cardiovascular implants

- Creates microscopically accurate features for diagnostic equipment components

- Produces consistent patterns in surgical tools with minimal material waste

- Enables rapid prototyping of new medical device designs

- Maintains sterilization requirements through non-contact cutting

The controlled heat affected zone of laser cutting helps you maintain material properties vital for medical applications. You’ll appreciate how this technology lets you work with various biocompatible materials, from metals to polymers, while guaranteeing each component meets strict regulatory standards. The process’s repeatability and documentation capabilities support FDA compliance requirements essential for medical device manufacturing.

Electronics and Circuit Board Production

In PCB manufacturing, you’ll find laser cutting machines performing precise trace isolation and board outline creation with exceptional accuracy. Your flexible circuit production benefits from laser systems that can process thin, bendable materials without mechanical stress or damage. These non-contact cutting methods enable you to achieve intricate patterns and complex geometries essential for modern electronic components.

PCB Manufacturing Applications

Laser cutting machines serve as indispensable tools in PCB manufacturing, offering precise control for creating intricate circuit board designs. You’ll find that pcb design innovations have revolutionized the way you can produce complex layouts with exceptional accuracy. Modern laser etching techniques allow you to achieve micro-level precision while maintaining consistency across multiple production runs.

- Allows high-precision cutting of copper traces with minimal thermal impact

- Creates perfectly sized vias and through-holes for component mounting

- Performs selective material removal for multi-layer PCB construction

- Achieves clean edge finishes without burrs or mechanical stress

- Supports rapid prototyping with quick design-to-production turnaround

When you’re working with advanced PCB designs, laser cutting technology guarantees you can meet tight tolerances while maintaining the structural integrity of delicate circuit pathways. The process eliminates many traditional manufacturing limitations, allowing for more sophisticated board layouts.

Flexible Circuit Production

Beyond traditional rigid PCB applications, flexible circuit production represents a specialized domain where laser cutting machines excel. You’ll find laser cutting invaluable when manufacturing flexible circuits due to its exceptional precision and ability to handle delicate materials without damage.

Laser cutting machines allow you to create intricate patterns and complex geometries in flexible circuit materials while maintaining tight tolerances. You can precisely cut copper traces, through-holes, and outline shapes with minimal thermal impact on surrounding areas. The laser precision guarantees clean edges and prevents delamination, which is vital for flexible circuits that need to bend and fold without compromising their electrical integrity. When you’re working with polyimide and other flexible substrates, laser cutting provides the accuracy and repeatability required for high-quality flexible circuit production.

Custom Gift and Trophy Creation

When creating personalized gifts and awards, laser cutting machines offer unmatched precision and versatility for crafting unique items. You’ll find these machines excel at producing custom trophies, plaques, and commemorative pieces through advanced engraving techniques. The technology allows you to work with various materials while maintaining consistent quality across multiple items.

- Precise etching of names, dates, and custom messages on metal, wood, or acrylic surfaces

- Creation of intricate 3D designs and layered effects for dimensional awards

- Rapid production of personalized awards for corporate events and ceremonies

- Custom cutting of shapes and patterns for unique gift presentations

- Integration of logos and branded elements with exact specifications

The laser cutting process guarantees clean edges and professional finishes on every piece. You’ll achieve detailed results that traditional engraving methods can’t match, making these machines invaluable for gift shops, trophy stores, and custom award manufacturers.

Prototype Development and Testing

Through rapid iteration and precise modifications, prototype development reaches new levels of efficiency with laser cutting technology. You’ll find that laser cutters enable quick creation and refinement of prototype designs, accelerating your product development cycle considerably. When you need to test multiple design variations, laser cutting machines deliver consistent results with exceptional accuracy.

Your prototype innovation capabilities expand as you’re able to cut intricate patterns and complex geometries in various materials. This versatility allows you to validate design concepts quickly and make immediate adjustments based on testing results. You can achieve testing efficiency by producing multiple iterations in a single production run, comparing different versions simultaneously.

The precision of laser cutting guarantees your prototypes maintain exact specifications throughout the testing phase. You’ll reduce development costs by identifying design flaws early and implementing improvements before moving to full-scale production. This streamlined approach helps you optimize your final product more effectively.

Aerospace Component Manufacturing

Laser cutting technology revolutionizes aerospace component manufacturing by meeting the industry’s demanding specifications for precision and reliability. When you’re working with aerospace design requirements, you’ll find that laser cutting offers unmatched accuracy for complex geometries while maintaining material integrity. This advanced process lets you fabricate intricate parts from lightweight materials without compromising structural strength.

- Achieves precision cuts in titanium, aluminum, and composite materials with tolerances as tight as ±0.1mm

- Creates complex cooling channels and ventilation systems in turbine components

- Produces lightweight, high-strength structural elements for aircraft frames

- Enables rapid prototyping of aerospace parts with minimal material waste

- Delivers consistent quality for safety-critical components that meet strict aviation standards

You’ll appreciate how laser cutting maintains material properties while achieving clean edges and precise dimensions, ensuring components meet rigorous aerospace certification requirements. The technology’s ability to work with various materials makes it invaluable for modern aircraft production.

Material Selection and Compatibility

Understanding material compatibility is essential before operating any laser cutting system, as different materials respond uniquely to various wavelengths and power settings. You’ll need to match your substrate choice with the appropriate laser type to achieve ideal cutting results.

CO2 lasers work effectively with non-metallic materials like wood, acrylic, leather, and paper. They’ll also process certain plastics, but you must verify compatibility to avoid harmful fumes. Fiber lasers excel at cutting metals, including steel, aluminum, and copper, while struggling with organic materials.

When selecting materials, you’ll need to take into account factors such as thickness, density, reflectivity, and thermal conductivity. These properties directly affect cutting speed and quality. You should also evaluate the material’s melting point, potential for discoloration, and edge finish requirements. Some materials may require specific assist gases or specialized ventilation systems to guarantee safe and efficient processing.

Conclusion

You’ll find that laser cutting machines serve as powerful, precise partners in modern manufacturing, from prototyping products to producing professional parts. These sophisticated systems seamlessly support sectors spanning from structural steel fabrication to delicate decorative designs. Whether you’re crafting complex components for aerospace applications or designing detailed displays, laser cutting technology delivers dependable, diverse, and dimensional results for your specific requirements.